Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Highest Expertise in Sensor Engineering

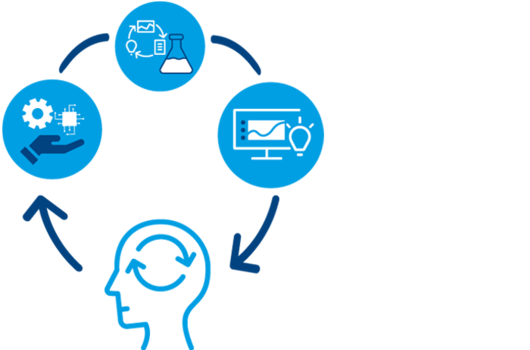

Being a step ahead of its competitors is the basis of each successfully working company. For this you will need new or further developed tools. Right from the beginning, PreSens Precision Sensing can be your partner while finding these new approaches: from specifications to implementation and up to production according to highest quality standards. Your customized solution comes from one expert source. PreSens relies on excellent sensor engineering know-how, which results in demand-orientated products "Made in Germany". Let our team be your competent partner!

As we offer high quality products, our measurement devices are also applied in sensitive processes, like e.g. medical drug manufacturing, oxygen free packaging or personalized medicine. To ensure highest quality standards from development, over serial production, up to application the quality management system is certified to EN ISO 13485 and ISO 9001.