Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Oxygen Permeation Measurement in PET Bottles

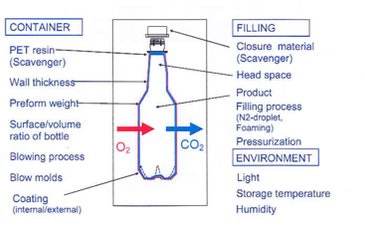

Oxygen causes chemical processes decreasing the shelf life and flavor quality of beverages in PET bottles, as the molecular structure of PET only offers an insufficient gas barrier against oxygen ingress and loss of CO2. Therefore, the permeability of PET bottles (material, seals, closures, etc.) needs to be matched with the sensitivity of the beverages and the specified shelf life. Some bottles must have nearly hermetic seals while others can (and sometimes must) be selectively permeable. And there is a manifold of additional factors affecting the shelf life (see left). In consequence, knowledge about the exact permeation rate is essential.

There are two common ways of determining the oxygen ingress in PET bottles: Firstly, the electrochemical measurement process, using a central module which is separated by the test film; Secondly, a measurement through intermittent contact. Then, some 10 years ago, a third method was established: the non-invasive measurement by using optical-chemical sensor technology, which allows to determine the oxygen permeability via detecting trace concentrations of oxygen inside the PET bottle. The PET bottle does not need to be destroyed and it allows to do any desired number of measurements with the same bottle. This is not only possible in the gas phase (head space), but also in the beverage itself, which is of great advantage in industrial applications. The sensing principle is based on a fluorescence quenching method, measuring the luminescence decay time. For this purpose an optical fiber transfers light to the sensor and the fluorescence signal back to a photodiode integrated in the oxygen permeation measurement device. This measurement technique enables long-term studies with low amount of samples and highly reliable data. Concentration levels of gaseous or dissolved oxygen can be detected with a limit of 1 ppb of dissolved oxygen.

Results with Different Bottle Types

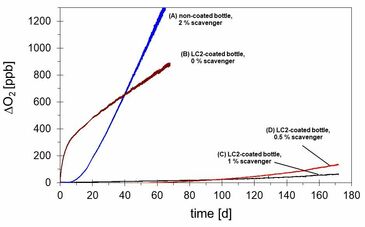

The figure left shows oxygen permeation measurements in differently treated PET bottles. They vary from external barrier coatings and inclusion of different amount of oxygen scavenger materials. These scavengers should prevent oxygen contained in the bottle material itself from migrating into the product. These are in detail:

- (A) non-coated PET bottle with 2 % scavenger,

- (B) LC2 coated PET bottle with no scavenger,

- (C) LC2 coated PET bottle with 1 % scavenger,

- (D) LC2 coated PET bottle with 0.5 % scavenger.

The combination system (C) and (D) maintain the oxygen ingress to less than 1 ppm over six months, which could be accomplished with the active (scavenger (A)) or passive (LC2 coating(B)) barrier alone. The sampling rate was adjusted to 30 seconds).

The results show that the amount of oxygen that will enter the product depends on the location of the coating (external or embedded) and whether an oxygen scavenger is used or not. The best performance is shown by bottles which use an active barrier (scavenger) additional to the passive barrier which is also acting as protection layer to prevent the reaction of the scavenger with atmospheric oxygen. This way a shelf life of more than 180 days can be reached even when the amount of scavenger is reduced.

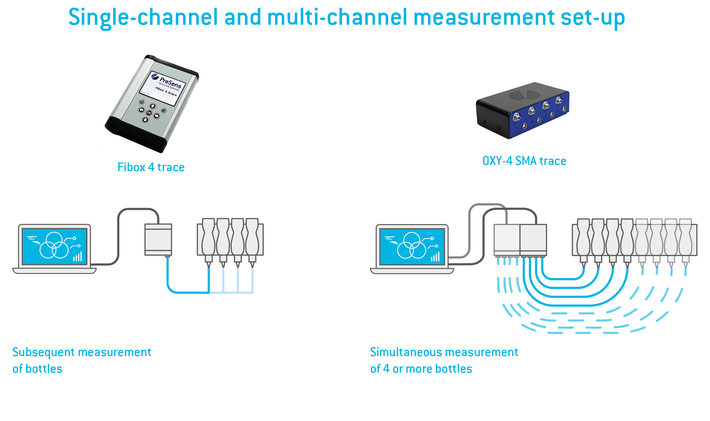

There are two possible set-ups for oxygen ingress measurements as shown in Fig. 3: by sequentially measuring several bottles with a single-channel device (Fibox 4 trace) or by simultaneous measurements of 4 or more bottles with a multi-channel device (OXY-4 SMA trace). Both set-ups work with the same database supported software (PreSens Measurement Studio 2). This intelligent sensor management allows easy handling of huge amounts of data and data transfer – for simultaneous measurements and set-ups of measurement networks, e. g. of two or more OXY-4 SMA trace at the same time.