Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Development of a New, Highly Sensitive Sensor for Permeation Measurement

Optical Sensors Used for Permeation Testing of High Barrier Materials

Christian Huber3, Sven Sängerlaub1, and Kajetan Müller2

1TU Munich, Chair of Food Packaging Technology, Freising, Germany

2Fraunhofer Institute for Process Engineering and Packaging, Freising, Germany

3PreSens Precision Sensing GmbH, Regensburg, Germany

A new measurement system for testing synthetic materials on oxygen permeability was developed. Unlike the currently used systems with electrochemical or barometrical sensors it was designed for optical measurement. The Fibox 4 trace together with chemical optical sensors was applied to detect trace oxygen concentrations and validate the new measurement system. Apart from an already available sensor type different other types of sensor material were tested to develop an oxygen sensor with an improved limit of detection for high barrier permeation measurements. This sensor type - PSt9 - together with the measurement cells seems to be a promising solution for easy, cost effective permeation measurements in technical applications.

Measuring the oxygen permeation rate of certain synthetic materials can help improve the shelf life of products or functionality of certain technical applications. Developing an easy-to-handle measurement device for permeation measurement could be a huge step forward. For most food applications a permeation measurement system would have to be able to detect in a measurement range of 0.05 - 2000 cm3/ (m2 d bar). But for technical applications like the development of LED displays, photovoltaic modules or vacuum insulating panels the lower measurement limit would have to be 10-3 cm3/(m2 d bar) - even lower for the development of OLED displays or organic solar cells (10-6 cm3/(m2 d bar)). The goal of this study was to develop a system, which allows effective permeation measurement without having to apply specialized gear and personnel, and that works with the same or even higher accuracy compared to the currently used systems. Measurement cells with improved leak tightness, made of stainless steel, were designed. For permeation measurements chemical optical sensors together with the Fibox 4 trace transmitter by PreSens were applied. To achieve even lower oxygen detection limits new sensor materials were tested so the system could also be applied for high barrier foils and packages.

Materials & Methods

A series of 16 measurement cells with different volumes were used in these experiments. The materials that should be tested for their barrier properties - film samples - were fixed between the upper and lower chamber of the measurement cell. Each chamber had two gas connectors, so first both chambers could be flushed with nitrogen (zero value). Then the lower chamber was flushed with oxygen. A chemical optical sensor spot (PreSens, Germany) was applied in the upper chamber to conduct permeation measurements. The sensor type PSt6 consists of an oxygen-sensitive dye embedded in a silicone matrix. The lower detection limit of a PSt6 sensor is 0.0025 % (25 ppm) oxygen in gas phase. This value is within the same range or even a level above commonly used measurement systems. Still, to conduct high barrier permeation measurements an even lower detection limit is needed. Therefore, different polymers with high oxygen permeation rate and several oxygen indicator dyes were tested to get a new and improved chemical optical sensor membrane. For validation of the measurement system the 100 µm PET film HOSTAPHAN® RN 100 was used to perform reference measurements.

Typical Measurement Reading

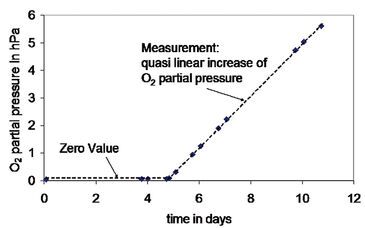

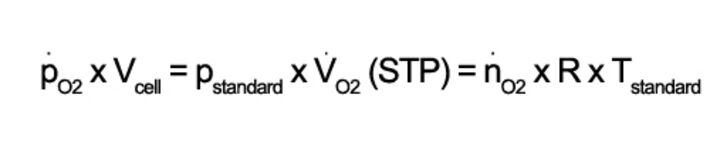

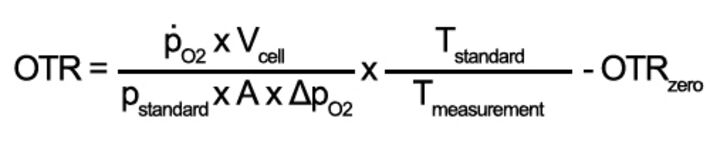

During zero measurement the oxygen partial pressure increased by 0 to 0.01 hPa after 5 days. This corresponds with a zero value for the permeation of 0 to 0.03 cm3/ (m2 d bar). The increase of oxygen partial pressure over time showed a quasi linear scope up to 40 hPa (see Fig. 2). Adapting the ideal gas law

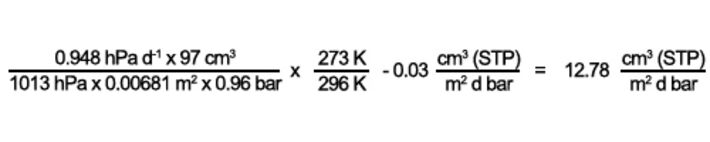

and considering the temperature during measurement, the oxygen transmission rate (OTR) could be calculated from the partial pressure increase, from the upper cell volume

Vcell, and the permeation area A:

After subtracting the zero value of 0.03 cm3 (STP)/ (m2 d bar), the oxygen permeation of this 100 µm PET film (HOSTAPHAN® RN 100) is 12.78 cm3 (STP)/ (m2 d bar). Con- ducting the experiments with high barrier films no change in oxygen partial pressure could be measured after 20 days so the zero value could be below 0.01 cm3/ (m2 d bar).

Validation of the System

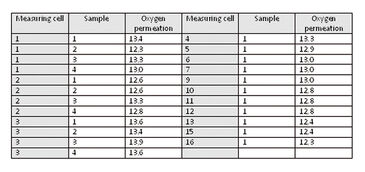

Reference measurements were performed with the 100 µm PET film HOSTAPHAN® RN 100 using the PSt6 sensor type. From over 100 single measurements the oxygen permeability of the film is known to be in a range of 12.26 to 14.10 (cm3 (STP) 100 µm)/ (m2 d bar) at 23 °C. All permeability values measured with the newly developed system were in this range (see Table 1). The accurate performance of the newly designed system is indicated by the low zero value and the correct measuring values of the reference films.

Measurement Range of the System

With carrier gas permeation methods it is not possible to measure films with very high permeability, since the absolute pressure difference between the upper and lower cells has to be zero. By checking permeability with optical sensors on the other hand it is possible to measure perforated and high permeable films. The highest measured permeability of a film was 2 x 107 cm3 (STP)/ (m2 d bar) for 30 µm PE film filled with CaCO3.

The lowest oxygen permeation value measured with the standard PSt6 sensor was 0.01 cm3 (STP)/ (m2 d bar) for a film with the layer composition PETmet / PETmet / PETmet / PE-LD with a thickness of 12 µm + 12 µm + 12 µm + 50 µm = 86 µm, usually used for encapsulation of vacuum insulation panels. In this special case it took about 4 weeks to measure a value of 0.01 cm3 (STP)/ (m2 d bar). Long measurement periods are necessary for high barrier material.

Testing different sensor materials the very sensitive oxygen membrane PSt9 seemed to be the most promising to expand the measurement range of the system. The oxygen indicator dye, a transition metal complex, was integrated in a special polymer matrix displaying a high oxygen permeation rate. The PSt9 sensor has a dynamic range of 0 - 1000 ppm and a limit of detection of 0.5 ppm gaseous oxygen.

Conclusion

Experiments in this study showed that chemical optical sensors can be used for permeation testing. Applying the PSt6 sensors the new measurement system allows detection of oxygen in a range of 10-2 to 107 cm3 (STP)/ (m2 d bar). This is ideal for measuring packaging materials for food applications. The new and more sensitive sensor spot PSt9 will offer an expected measurement range between 10-3 and 100 cm3 (STP)/ (m2 d bar). Applying this sensor type the new system might be suitable for measurement of films used in technical applications. But this will have to be validated in further tests. The new measurement system together with the PSt9 sensor will be an easy-to-use and cost effective method to determine oxygen permeability of important synthetic materials.