Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Non-invasive pH Monitoring in Anaerobic Clostridium Culture

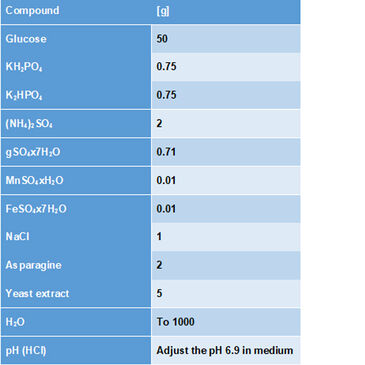

Evaluation of the pH Sensor Spot SP-LG1 in Low pH Range

Nikola Naschitzki

Beuth University of Applied Sciences, Berlin, Germany

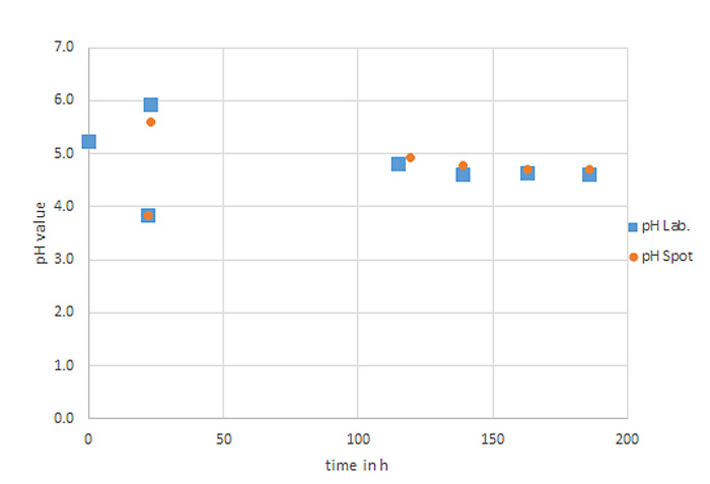

A prototype pH sensor spot type LG1 was integrated in a closed, gas-tight culture bottle for monitoring an anaerobic cultivation of Clostridium acetobutylicum. The sensor allowed non-invasive measurements through the bottle wall. We evaluated the sensor's ability to give correct readings in the lower pH range down to pH 3.5. Therefore, measurements in the anaerobic culture were compared to reference measurements with a laboratory pH probe. Although the control software caused problems, the measurement data could be retrieved and compared to the reference measurements. The values measured with the pH sensor spot were sufficiently accurate in a rate of pH 6 - 3.84 with an average deviation of 0.14 from the reference values.

The biotechnological importance of C. acetobutylicum is based on its ability to produce acetone, butanol and ethanol in fermentation (ABE-fermentation). In this study, the bacteria were grown in anaerobic conditions and pH was measured with an optical measurement system. The non-invasive measurement principle of optical sensors is an ideal solution for monitoring fermentation processes, as there is no need to open the culture vessel and accidental oxygen ingress can be avoided. Furthermore, pH development inside the culture can be followed online during the whole process. New prototype sensor spots by PreSens with a broader measurement range were used, together with a pH-1 SMA LG1 module to measure in a closed, gas-tight bottle with C. acetobutylicum culture. As the pH values can drop as low as pH 3.5 during fermentation and this sensor had not been tested in such conditions before, its accuracy in the lower pH range was evaluated by comparing the measurement results with reference values from a laboratory probe.

Materials & Methods

Clostridium acetobutylicum DSM 792 was cultivated in anaerobic Clostridium Growth Medium (CGM, media composition in Tab. 1) inside a closed, gas-tight glass bottle. The anaerobic cultivations were carried out inside an incubator at 37 °C, without shaking.

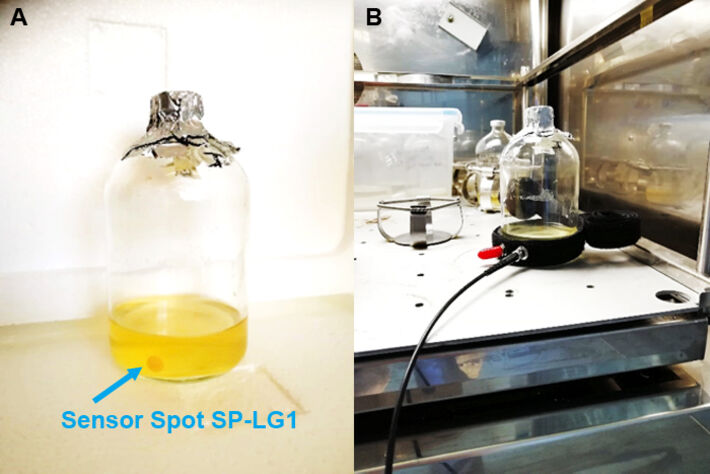

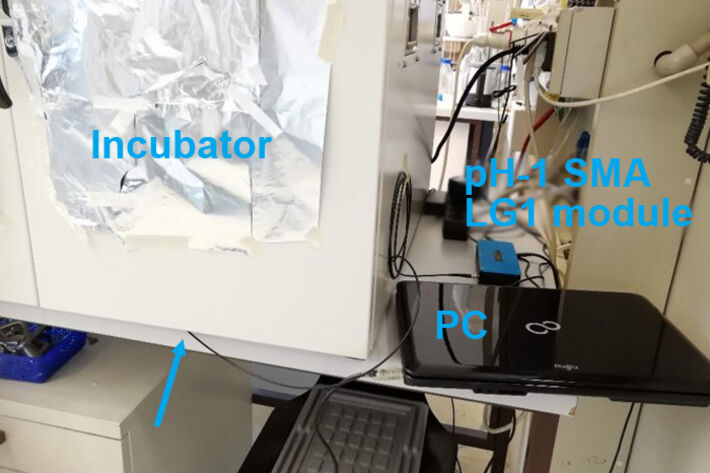

The pH senor spot (SP-LG1) was attached to the inside bottle wall near the bottom (Fig. 1A). The sensor was read out from the outside via a polymer optical fiber, which was held in place with a velcro®-type adapter (Adapter for Round Containers ARC, Fig. 1B). The fiber was lead through the incubator door sealing and connected to the pH-1 SMA LG-1 on the outside (Fig. 2). The measurement system was controlled with the pH-1 View software (versions 1.2.6.0 and 1.2.2.0). For later experiments, ComLog 11 was used for direct access to the pH-1 SMA LG1 and data recording.

pH Monitoring during ABE-Fermentation

During initial tests with the optical pH measurement system different errors occurred in the pH-1 View EOM software. It was decided to use ComLog 11 and get direct access to the measurement unit. This way it was possible to record the measurement data, though with this software we were not able to get a graphical display of the pH development.

Figure 3 shows the values measured by the prototype pH measurement system compared to measurements with a laboratory pH probe in C. acetobutylicum culture over 186 h. After 22 hours the culture pH was adjusted from pH 3.8 to pH 6 by addition of CaCO3. At this time, the values measured with the sensor spot showed the largest deviation from the reference values. This was probably caused by insufficient equilibration of the sensor spot inside the culture to the new pH value. In the following measurements, both the values taken with the sensor spot and the reference probe were in good accordance with an average deviation of 0.14. We can therefore deduce that the sensor spot gave accurate pH measurements in a range from pH 6 to pH 3.84.

Conclusion

The non-invasive pH measurement system and the prototype sensor spot SP-LG1 are very well suited for this type of application. It is a great advantage to be able to measure through the culture vessel wall and maintain anaerobic conditions. In these tests, we could show that the sensor gave accurate readings, also in the lower pH range. However, the software would need to be better adapted to the prototype measurement system. Currently development is on the way to operate this pH measurement unit with a new version of the PreSens Measurement Studio 2 software.