Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Role of Oak Wood Ellagitannins on the Oxygen Transfer Rate in Wine Barrels

2D Visualization of Oxygen Permeation with VisiSens

I. Nevares Domínguez, M. del Alamo, C. González, and R. Crespo

UVaMOX, Universidad de Valladolid, Palencia, Spain

Oxygen permeation through oak wood in a wine barrel scenario has been recorded with the VisiSens™ oxygen imaging system. A special measurement chamber was designed to simulate realistic conditions and a piece of oak wood cut from a wine barrel stave was fixed inside. Measurements were taken under dry and wet wood conditions. The oxygen images taken with VisiSens™ showed promising results, confirming that oak wood is permeable for oxygen under both conditions, though the moisture content of wood reduces oxygen permeation. Being able to monitor oxygen permeation in 2D and under realistic conditions is a great advantage and therefore VisiSens™ will be considered as an adequate measurement tool for further studies examining oxidation of wood hydro-soluble compounds and the theoretical formation of an oxygen barrier inside the wood.

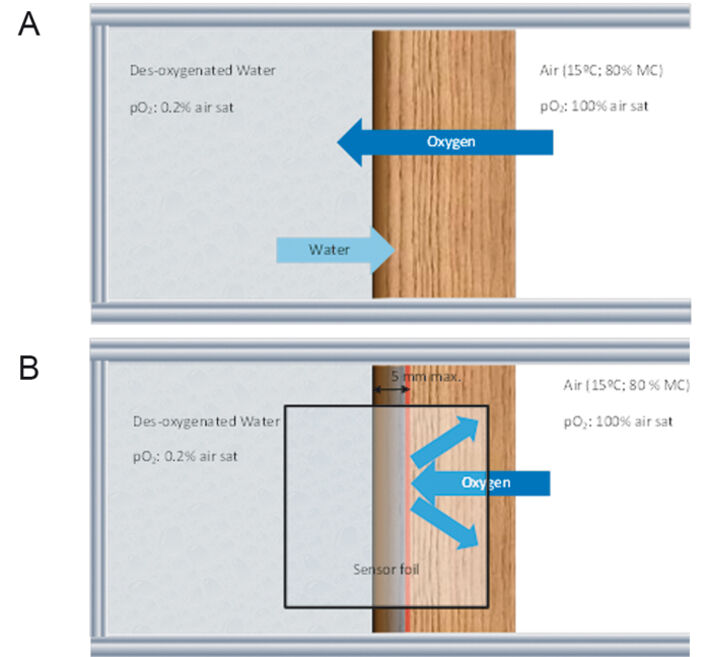

Several researchers have evaluated the oxygen transfer rate (OTR) of oak barrels filled with wine, this value ranging from 20 to 65 mg/L year in new oak barrels. However, there is no detailed information on how the oxygen diffuses through the oak wood. When the barrel is full of wine, the wood is in contact with the liquid and its moisture content (MC) increased until saturation. Some authors described this wet layer being between 1 - 2 mm thick, but it can also have up to 5 mm thickness depending on oak species. The main characteristics of red wine aged in barrels is the slow and constant intake of oxygen through the barrel staves and gradual dissolution of ellagitannins, which constitute an effective buffer against oxidation during the aging process. However, this theory has not been demonstrated on an experimental basis. These wood hydro-soluble ellagitannins would form an oxidized layer which avoids the oxygen diffusion through the oak staves. If that layer works as an oxygen barrier then how is the wine oxidized? In these experiments we applied the VisiSens™ oxygen imaging system for 2D visualization of oxygen movement through the wood. A special chamber was constructed to recreate the oak barrel scenario.

Materials & Methods

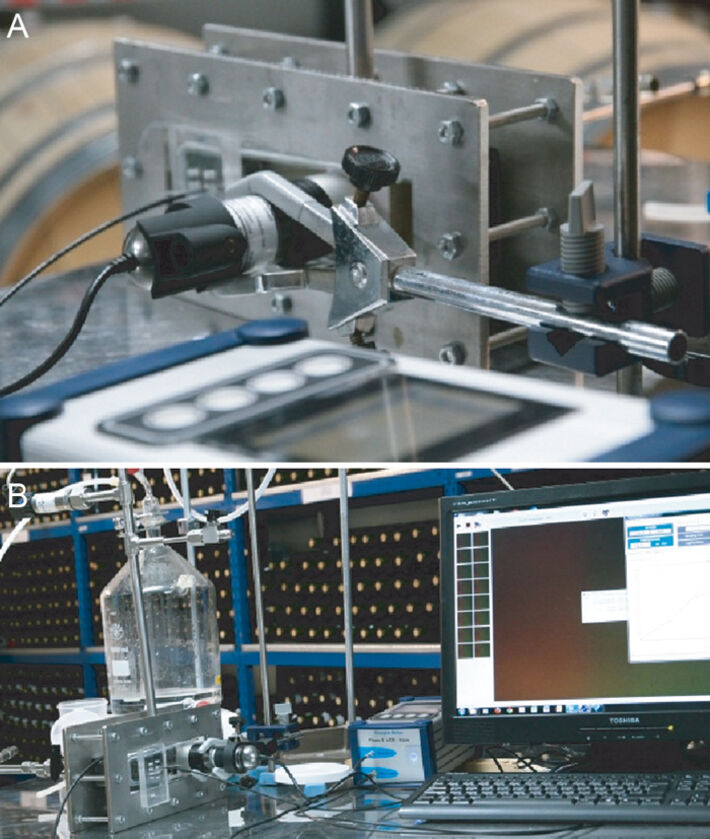

A special chamber was designed to simulate conditions in an oak barrel filled with liquid, with one transparent side, to which an oxygen-sensitive sensor foil was glued. The entire device was built from stainless steel with Viton gaskets to assure air tightness. An oak wood piece, directly cut from a barrel stave, was attached to the chamber with epoxy. Wine was replaced with water, as wine is an oxygen scavenger and would falsify permeation measurement. Figure 1 A shows the initial conditions when the oak wood piece of a barrel stave is in contact with water. Next to it in Figure 1 B the situation postulated by other authors is displayed, when oak becomes wet and the oxygen buffer layer is working. The relation of wood surface / liquid volume (S/V) of a 225 L oak wine barrel was applied to the measuring chamber in order to determine the OTR directly. To measure DO evolution in the liquid the Fibox 3 LCD trace in combination with a trace oxygen sensor (type PSt6, PreSens) was used. For monitoring and 2D visualization of DO distributions in the wood-water interphase but also in the adjoining layers of wood in contact with water, the VisiSens™ oxygen imaging system combined with an oxygen sensor foil (SF-RPSu4, 40 x 40 mm2) was applied. The set-up of the oxygen measurement tools is shown in Figures 2 A + B. When all systems were installed, the liquid chamber was flushed with nitrogen. Then the liquid side of the chamber was filled with deoxygenated water impelled by nitrogen flow to avoid air contamination. For the first 5 h oxygen measurements were taken every minute, and between 5 and 24 h of the experiment at 5 min intervals. The first 24 h were considered the dry wood situation. After the first day the water remained in the chamber and several deoxygenation cycles were performed. The wood then was kept in contact with the liquid for two weeks to achieve the wet wood situation, and the same 24 h-period recordings were performed. The oxygen transfer from the surrounding air through the oak wood and into the water at those two different conditions was compared.

OTR in Dry and Wet Oak Wood

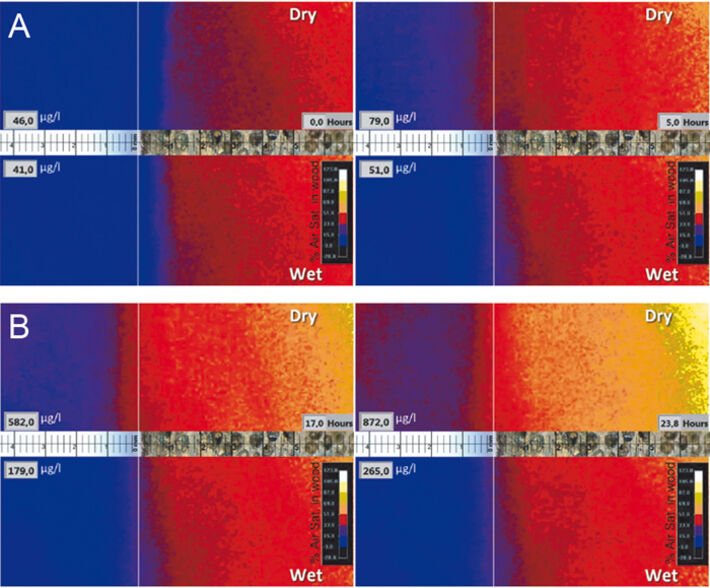

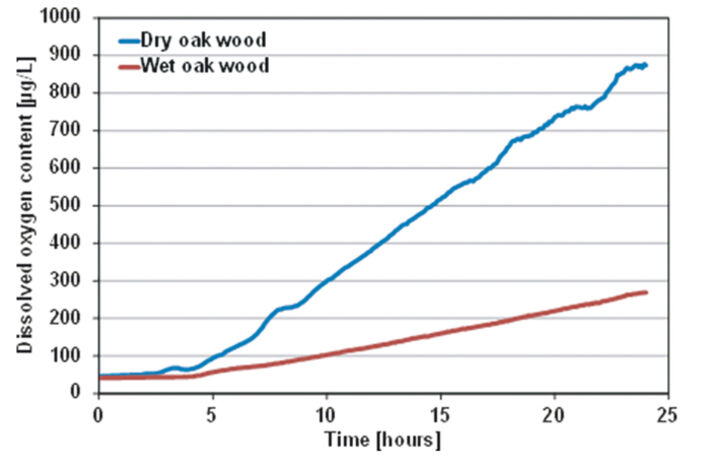

The oxygen measurements taken under realistic conditions - like in a real wine barrel - showed very promising results. The white vertical line in Figure 3 indicates the wood-water boundary. The initial stage at 0 h shows the infiltration of deoxygenated water in the adjacent dry wood layer while under wet conditions this layer is already soaked (37 - 53 % air sat. in wood). After 5 h the oxygen desorption in dry wood is clearly observable, while in wet wood this process is much slower. Oxygen diffusion from wood into the water and a DO gradient are evident in dry conditions, while hardly observable in the wet wood. The oxygen permeation into water is 50 % higher in dry wood than it is in wet wood. Measurements taken after 17 h show similar results as after 5 h, but the real DO content in the water is higher. The growing DO content due to diffusion processes within the wood shows in the oxygen images. This situation is even more evident in the final stage of the trial, when the dry wood reaches air saturation, even though the oxygen partial pressure gradient is smaller than in previous stages of the experiment. The OTR of oak wood under both conditions was calculated with values of 83 and 302 mg/L year for wet and dry wood respectively (Fig. 4).

Conclusion

VisiSens™ allowed assessment of oxygen permeation through oak wood in a wine barrel scenario. These promising preliminary results confirm that oak wood is permeable to oxygen in both situations, dry and wet. The moisture content of wood acts as an oxygen permeation barrier because of the lower oxygen diffusivity in water than in air, confirming published works. However, some oxygen still diffuses from wood into the water when the oak wood is soaked. The VisiSens™ system is an adequate technique for studying the oxidation of wood hydro-soluble compounds and the theoretical formation of oxygen barriers. As the time period of wood being in contact with liquid seems to be a key factor in OTR evolution long-term measurements should be carried out in future studies.