Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Yeast Propagation at Brewery Scale

Oxygen measurements in the gas and liquid phase with OXYPro® WR

C. Krause & C. Huber

PreSens Precision Sensing GmbH, Regensburg, Germany

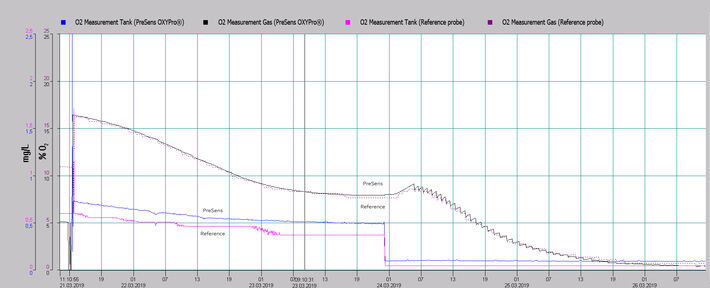

During propagation of the bottom-fermenting yeast strain Saccharomyces pastorianus spp. carlsbergensis in a 340 hl tank, oxygen was measured both in the liquid and in the gas phase with the oxygen probe OXYPro® to monitor and control the aeration rate. The values measured with OXYPro® were compared with measurements of a reference probe. While the measurements in the circulation line showed a difference of ± 0.1 mg/L on average between OXYPro® and the reference probe, the measured values of both probes in the exhaust air were almost identical.

In the propagation of S. pastorianus spp carlsbergensis, the bottom-fermenting yeast strain is cultured in aerobe conditions, with the aim to produce biomass while maintaining high vitality and viability. After reaching the desired cell concentration, the yeast is stored until use. The objectives of this process are (a) to maintain a reproducible high quality yeast growth and (b) to maintain this quality until yeast application, or (c) to control the process so that no storage is needed (i.e. shortening or lengthening propagation depending on production planning). The manipulated variables that can be changed in the process are the temperature, the aeration rate and intensity, and the inoculum concentration, whereby an increase in these parameters results in a shortening of the process time, with simultaneous loss of quality.

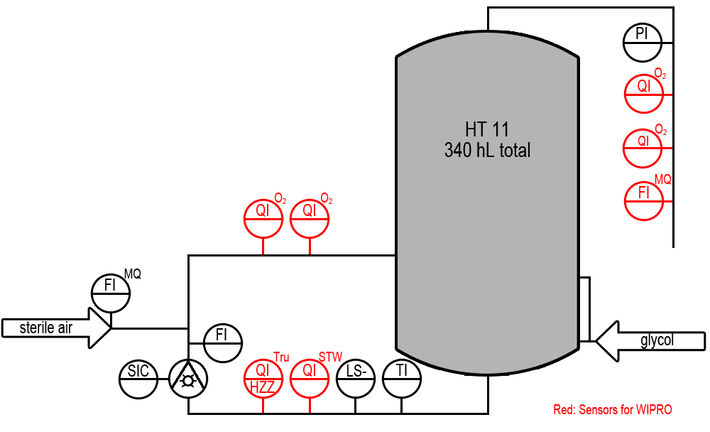

In breweries, sensors are usually integrated in Varivent vales to measure directly in the product. The OXYPro® WR wide-range oxygen probe can be combined with the Varivent adapter, an accessory that attaches to the probe via the PG 13.5 thread. This adapter allows easy and safe integration of the probe into the valve (see Fig. 1). The OXYPro® is then connected to the central control unit and in-line oxygen measurements can be made. In addition, these probes withstand cleaning under CIP conditions, a prerequisite for application in breweries. Two of these probes were integrated at different positions in the process to determine the oxygen content both in the culture medium and in the exhaust air.

Material & Methods

S. pastorianus spp. carlsbergensis was cultured in wort in a 340 hl tank with a reaction volume of 110 hl and an inoculum volume of 10 % v/v. During propagation, the temperature was constantly regulated to 12 °C and the culture gassed linearly with 1.1 Nm3/h of sterile air. The oxygen concentration during propagation was set to 0.4 mg/L.

The OXYPro®, along with other sensors was connected to the control cabinet, which was connected to the ProLeit process control system (ProLeiT AG, Germany) via Profibus. The OXYPro® oxygen measurements were compared to values from reference probes from another manufacturer. The OXYPro® WR was integrated in the circulation line via a Varivent valve. The reference probe was also installed in the line. For gas phase measurements, the OXYPro® was mounted in the exhaust duct while the reference probe was mounted in the tank dome. The probes were cleaned in CIP conditions (2 % NaOH, active chlorine, HNO3 < 1 %, peracetic acid, T ≤ 50 °C) after the process.

Results

Figure 3 shows the oxygen measurements with two OXYPro® WR and two reference probes during a yeast propagation process in a 340 hl tank. During yeast growth, the oxygen content in the tank was regulated to 0.4 mg/L. After 4 days, the propagation was completed, the tank cooling started and the aeration was turned off, clearly visible by the sudden drop in oxygen curves recorded in the circulation line. The measurements of OXYPro® and reference probes showed a similar course during the whole process. In the liquid phase, however, the optical oxygen probe and the reference probe exhibited a measurement difference of 0.1 mg/L on average, presumably due to different calibration procedures for the two probes. In contrast, the measurements in the exhaust air are almost identical for both probes, even though they were installed in different locations (OXYPro®: exhaust air duct, reference probe: tank dome). After the aeration was shut off, the tank was pressurized with sterile air, which can be seen in a slight oxygen increase in the exhaust air. At this time, the oxygen and CO2 levels in the tank were in equilibrium. As the yeast had stopped growing and started fermentation, the produced CO2 increased the pressure in the tank, the tank was gradually depressurized, which led to a temporary decrease in oxygen levels in the exhaust air, or in the gas phase over the culture medium, and shows in the jagged course of the exhaust air measurements of the two probes. It was found that the OXYPro® probe was able to dissolve the intermittent venting better than the reference probe due to better time resolution.

Conclusion

The OXYPro® wide-range oxygen probes are ideal for measurements at brewery scale. With the adapter, the probes can easily be installed at the measuring location and can withstand CIP conditions. Our experiments show that they are in good accordance with measurements of reference probes. Connected to the process control system, they enable the continuous control of propagation processes and thus contribute to maintaining consistent quality in beer production.

These investigations were carried out as part of the WIPRO II project funded by the BMBF (grant number 031B0475J).