Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Mechanical & Electronic Design

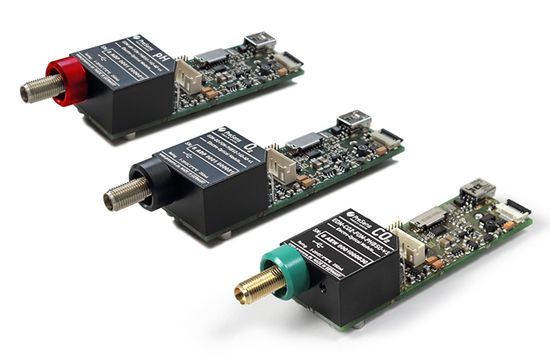

Electronics for Optical Measurements

PreSens offers electronics for optical O2, pH, CO2 or biomass measurements. Modules can evaluate just one analyte or several of these parameters in parallel. Furthermore, multi-channel OEM components can be developed for simultaneous measurements in multiple samples, e. g. for screenings in small volumes.

State of the Art Engineering Tools

In our in-house workshops, our engineers develop, produce, and test all new parts - from high precision optics to tailored device housings. They use high quality milled and turned metal optics parts as well as 3D-printing (e.g. FDM, DLP) for design studies and prototype series. Laser plotters and fiber-lasers are used for prototyping, labeling, and marking all kinds of materials. For research purposes as well as highly integrated sensor applications like microfluidics our engineers also employ a UKP laser.

Your Customized Measurement Electronics

Our development team designs measurement electronics according to your specifications. Numerous solutions for PCB design, or different types of digital interfaces (e.g. RS232, RS485, USB, wireless communication) can be implemented for you. PreSens can develop battery-powered, stand-alone instruments or provide measurement electronics that meet low power requirements, making your end-user device not only more functional but also economical.

Industrial Standard Communication Protocols

PreSens OEM components are driven by PreSens proprietary or industrial standard communication protocols like Modbus RTU via RS485 or Modbus TCP facilitating integration into process control loops or IOT environments. Our firmware developers realize special measurement functions according to your requirements.