Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Perfusion monitoring in pipes

Oxygen Sensor Integrated in Metal Flow-Through Cell FTM-M10-PSt3

An Oxygen Exchange Cap (OEC-M10) with PSt3 sensor (max. measurement range 0 - 100 % O2, limit of detection 0.03 % O2) is integrated in a metal flow-through cell via M10 thread. The FTM is available with connector diameters of 6 mm, 1/4" or 1/2" and can be connected to pipes with other diameters using the respective adapters. For sensor read-out an optical fiber is connected. Fibers covered in a protective metal spiral tube can be connected to the FTM magnetically. The oxygen probe is very robust and long-term stable. It can be cleaned by CIP (Cleaning in place, + 80 °C and 2 % NaOH) and stands steam sterilization (+ 130 °C, 1.5 atm). The OEC-M10 can easily be exchanged, if necessary.

- Max. measurement range 0 - 100 % O2, limit of detection 0.03 % O2

- Different FTM sizes available

- No consumption of oxygen

- Signal independent of flow velocity

- Autoclavable, SIP (130 °C, 1.5 atm) & CIP (+ 80 °C, 2 % NaOH)

Applications

In-line Oxygen Measurement in Brewing and Beverage Industry

Even low concentrations of oxygen influence shelf-life and the taste of certain beverages. Due to the extraordinary low detection limit and outstanding accuracy of PreSens trace oxygen sensors, the quality of oxygen-sensitive products such as beer, wine and soft drinks is secured.

The optical sensors have – compared to standard electrodes – a very fast response time and they are very easy to maintain.

Technical

| Specifications | Gaseous & Dissolved O2 | Dissolved O2 | |||||

|---|---|---|---|---|---|---|---|

| *at 20 °C, 960 - 980 hPa; humidified gas mixture **after customized calibration ***determined changing from 20.9 % oxygen gas to nitrogen 5.0 ****determined changing from air-saturated water to a freshly prepared 1 % sodium sulfite solution | |||||||

| Measurement range* | Optimal: 0 - 50 % O2, 0 - 500 hPa Max.**: 0 - 100 % O2, 0 - 1000 hPa | Optimal: 0 - 22.5 mg/L Max.**: 0 - 45.0 mg/L | |||||

| Limit of detection* | 0.03 % O2 | 0.020 mg/L | |||||

| Resolution* | 1 % O2 ± 0.02 % O2 20.9 % O2 ± 0.1 % O2 50 % O2 ± 0.4 % O2 | 0.4 mg/L ± 0.009 mg/L 9 mg/L ± 0.04 mg/L | |||||

| Response time (t90) | < 10 sec.*** | < 30 sec.**** | |||||

| Properties | |||||||

| Compatibility | Aqueous solutions, ethanol, methanol | ||||||

| No cross-sensitivity | pH 1 - 14, CO2, H2S, SO2, ionic species | ||||||

| Cross-sensitivity | Organic solvents such as pure acetone, toluene, chloroform or methylene chloride Chlorine gas | ||||||

| Sterilization procedure | Steam sterilization Ethylene oxide (EtO) Gamma irradiation | ||||||

| Cleaning procedure | Cleaning in place (CIP, 2 % NaOH, + 80 °C, + 176 °F) 3 % H2O2 Acidic agents (HCl, H2SO4), max. 4 % - 5 % | ||||||

| Calibration | Two-point calibration with oxygen-free environment (nitrogen, sodium sulfite) and air-saturated environment | ||||||

| Storage stability | 5 years provided the sensor material is stored at room temperature in dry conditions and in the dark | ||||||

| Pressure resistance | 10 mbar up to 20 bar | ||||||

| Temperature range operation | Optimal: 0 °C to + 50 °C Max.: - 40 °C to + 90 °C | ||||||

| Temperature range storage | Optimal: room temperature (+ 20 °C ± 5 °C) Max.: 0 °C to + 70 °C | ||||||

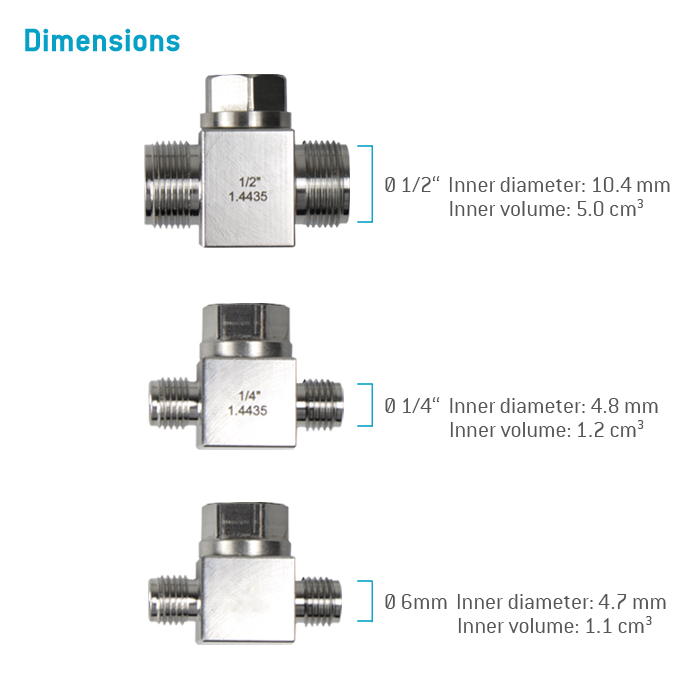

| FTM-M10 formats | Connector diameter | 6 mm | 1/4" | 1/2" | |||

| Inner diameter | 4.7 mm | 4.8 mm | 10.4 mm | ||||

| Inner volume | 1.1 cm3 | 1.2 cm3 | 5.0 cm3 | ||||

| Material | Stainless steel 316L (body), 304 (OEC-M10) | ||||||