Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Sensors for Online Monitoring of O2, pH and CO2 in Microfluidics and Millifluidics

Microfluidics and Millifluidics - or the study and manipulation of the liquid behavior in micro-channels - are an emerging technology, and already provide efficient tools for various science fields from biological and medical research to chemistry and engineering. Microfluidic devices make use of physical and chemical properties of liquids and gases at the microscale and offer many advantages:

- Less sample volume, low reagent consumption, cost reduction

- Minor sample handling and reduced exposure to dangerous chemicals

- Simplified process handling for end-users

- Multiplexed assays & high-throughput analyses

- Compact size & portability

- Easier automation and parallelization

- Shorter experiment times, faster reaction time

- Enhanced parameter control & analytical sensitivity

A microfluidic chip consists of micro-channels that are molded or engraved in a suitable chip material. Liquid is introduced and removed from this microfluidic chip through pathways. The micro-channel design has to be adapted to the respective application to achieve the desired features.

One goal in microfluidics is to integrate lab routines in one device and thus create a lab-on-a-chip (LOC). Development in this area has already made great progress and enables the application of microfluidics in many research areas.

Especially medical research can profit from investigations at microscale. The aim is to create 3D cell culture micro-devices to reproduce key functions of living organs - organs-on-a-chip. Compared to conventional cell culture, microfluidics are able to mimic microenvironments as well as their influence on the organ function.

Using microfluidic chips for cell culture has many advantages, but also holds some challenges. As the cells are enclosed inside the chip and separated from the environment, direct monitoring of important culture parameters like O2, pH and CO2 is difficult. Chemical-optical sensors are perfectly suited for monitoring in microfluidics:

- Different formats for diverse microfluidic or millifluidic devices

- Non-invasive read-out through transparent chip material

- Monitoring in small sample volumes, no sampling

- Signals are independent from flow velocity

- No consumption of the analytes

In all our different sensor formats the fluorophores are immobilized an incorporated in well biocompatible polymer membranes. This prevents dye leakage and any impacts on living samples that can occur when using pure dyes or nanoparticles which is especially important for organ-on-a-chip applications.

Following are our basic configurations for sensors for micro- and millifluidics:

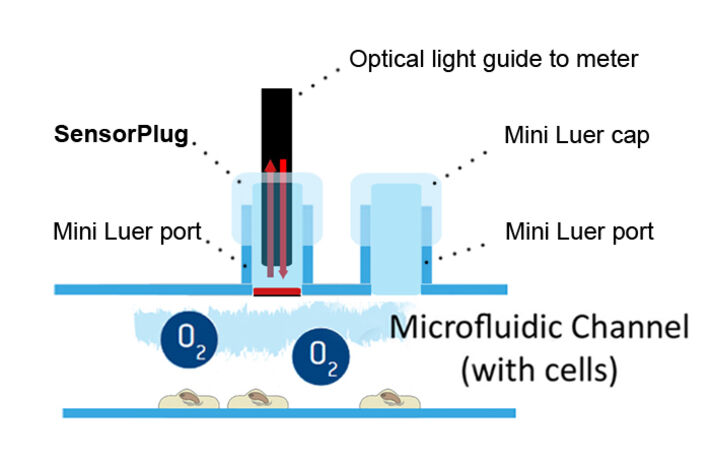

SensorPlugs and Fiber Optic Meters

SensorPlugs are specially designed for microfluidic and millifluidic applications. The sensor is attached to the tip of a plug, which is inserted in the corresponding port on the chip so the spot is in contact with the sample inside the channel. The standard version of the SensorPlugs is based on a Mini-Luer, which is carrying a 2 mm sensor spot. OEM versions for different ports are available. Each SensorPlug comes with an additional plain plug so the port can also be simply closed without having a SensorPlug on the chip for monitoring. SensorPlugs come pre-calibrated and beta irradiated.

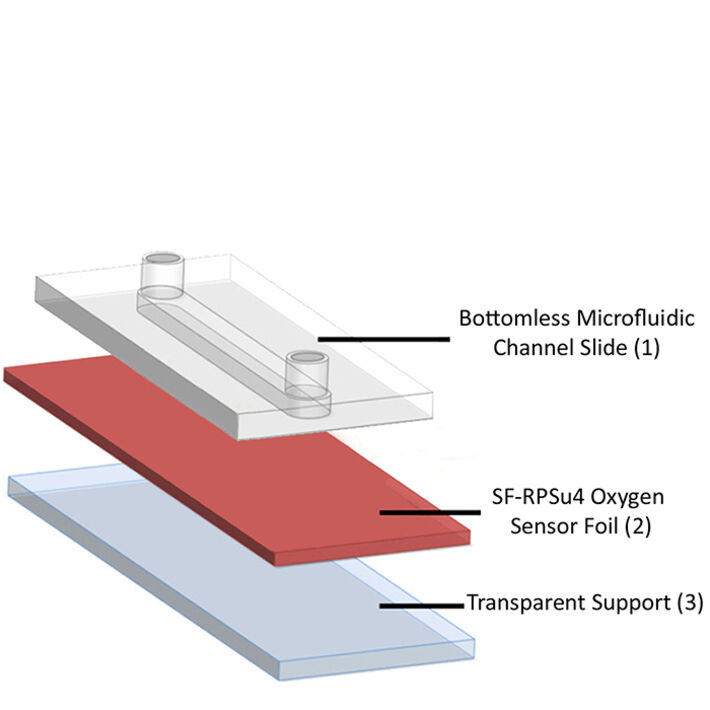

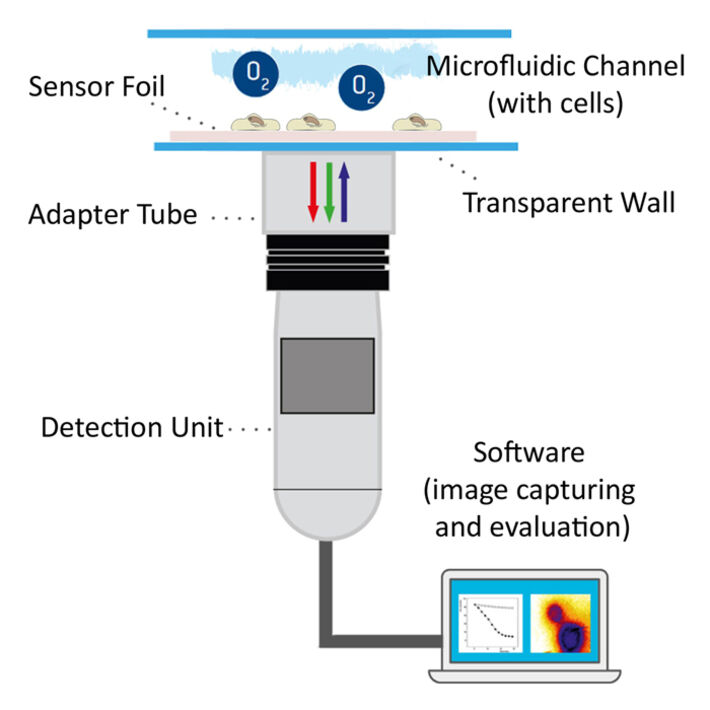

Sensor Foils and VisiSens™ Imaging System

Planar optodes can be integrated as an additional layer between bottom and top across the entire chip and the complete channel structure during assembly. This does not change the channel geometry and is especially useful during chip design to evaluate gradients and mixing efficiency, or for gradient chips in general. Cells can be seeded directly on the foils. A pre-treatment may be necessary to facilitate cell seeding.

The imaging is based on FRIM and VisiSens™ detection units are applied for the 2D read-out of the sensor foil through the transparent chip material. The respective software support calibration and basic image evaluation as well as export to standard image evaluation software tools like ImageJ. Calibration has to be performed in the respective set-up. The foils cannot be combined with conventional microscopy. The maximum spatial resolution that can be obtained is 25 µm (O2 sensor foil SF-RPSu4 without optical isolation layer).

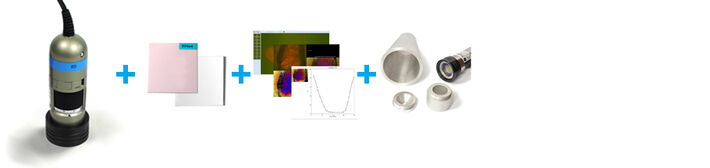

Set-Up

- VisiSens™ detector unit + Sensor Foil + VisiSens™ AnalytiCal software + Adapter tube (optional)

Flow-Through Cells and Fiber Optic Meters

Flow-through cells (FTCs) with integrated optical sensors for O2, pH or CO2 can be connected to the tubing at the microfluidic chip's inlet and outlet. Via polymer optical fiber the FTCs are connected to small readers. The fiber optic meters are controlled from one software that allows to follow measurements online. FTCs are available in different formats with different inner volumes starting from 2.1 µL. Sterile versions (beta irradiated) are available.

Sensor Spots and Fiber Optic Meters

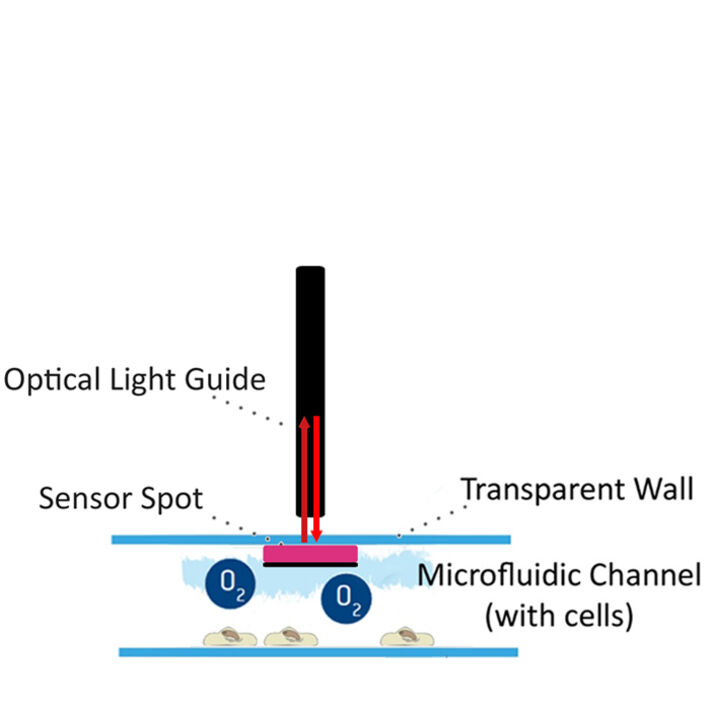

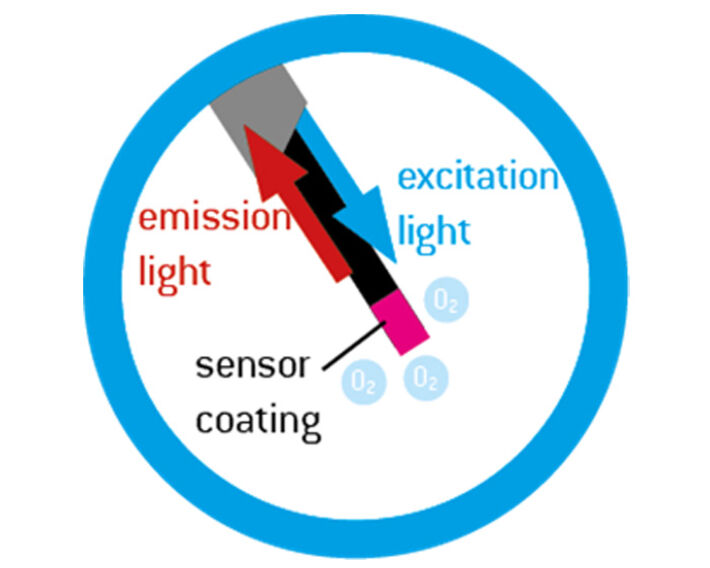

Sensor spots for O2, pH and CO2 can be integrated directly into the channels (top or bottom) via gluing prior to chip sealing. Spot diameter and thickness of the sensor spots have to be taken into account as well as sterility and cleaning. Sensor spots can be delivered beta irradiated. Autoclaving is not possible or rather autoclavable spots are not suited for microfluidics due to their thickness of several mm. Spots suited for microfluidics have diameters starting from at least 2 mm, and a thickness of at least 75 µm. The spots are read out via a polymer optical fiber that is positioned outside the chip opposite the spot. The fiber is connected to the respective meter, which is controlled via software.

Microsensors and Fiber Optic Meters

Microsensors for O2 and pH are based on very thin glass fibers carrying the sensor material on the tip. The fibers are housed in stainless steel cannulas. These sensors are fragile and usually exclusively suited for soft PDMS microfluidic ships that allow for direct piercing of the chip material with the cannula. The sensor tip is extended into the channel to get in contact with the sample. The minimum tip diameter is 50 µm.

Set-Up

- Compact fiber optic meter + Needle-type optical microsensor + PreSens Measurement Studio 2 software

OEM Components

All PreSens sensors - whether it is spots, FTCs, microsensors or SensorPlugs - can also be used with special Electro Optical Modules (EOMs). These boards can be integrated in custom control units. PreSens offers software solutions and communication protocols, so the sensor data can be embedded into your microfluidic device controls.