Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Characterizing CHO Cell Lines with SFR vario

What online measured data can tell about your cell culture

R. W. Maschke1, B. Pretzner2, G. T. John3, D. Eibl1

1Zurich University of Applied Sciences, Institute of Chemistry and Biotechnology, Wädenswil, Switzerland

2Werum IT Solutions GmbH, Vienna, Austria

3PreSens Precision Sensing GmbH, Regensburg, Germany

There are numerous CHO cell lines with different properties. They need to be characterized before starting a production process, to ensure the cells are suitable for the planned application. The SFR vario is a multiparameter monitoring platform for shake flask culture and delivers online data for oxygen, pH and biomass. In this report we give a few examples on how this online monitoring device can be used to characterize precultures of CHO cell lines before starting a bioreactor run.

CHO cells can easily be grown in suspension culture and are therefore widely used in research or for protein production processes. Many variants of the cell line have been developed, since the establishment of the original CHO cell line in 1956 [1]. Precultures at shake flask scale are often not controlled and the growth rate needs to be determined in offline measurements. In order to characterize the CHO cell lines in our laboratory before starting larger scale production processes, we used the SFR vario online monitoring platform for cell growth determination and inoculum tests at shake flask scale. Furthermore, SFR vario allows determining biomass development online via backscattered light measurements, and we also evaluated this measurement method for CHO cell culture.

Materials & Methods

The CHO DP-12 cells (clone 1934, courtesy of Prof. Noll, Bielefeld) were grown in TC42 medium (Xell AG) and the inoculation viable cell density was 0.3 x 106 cells mL-1. The cultivations were performed in 250 mL shake flasks without baffles with 80 mL working volume. The incubation conditions were 37 °C, 7.5 % CO2 and 80 % humidity, at 120 rpm and 50 mm shaking diameter. The measurement angle for biomass measurements with the SFR vario was not adjusted. Data collection and evaluation were carried out using inCyght by Werum IT Solutions.

Growth Rate Determination with Online Data

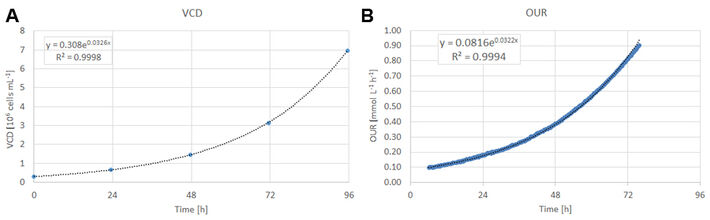

Fig. 2A shows the growth rate of CHO DP-12 cell culture determined with conventional offline measurements. Samples have been taken every 24 h for viable and total cell density analysis. An exponential fit can be applied to determine the maximum growth rate:

where cx(t) is the viable cell density at time t, cx0 is the starting viable cell density and µmax the maximum growth rate. With offline data a maximum growth rate of µmax = 0.0326 h-1 was determined for the CHO cell culture.

In Fig. 2B online recorded SFR vario data for the oxygen uptake rate (OUR) is plotted. Again, an exponential fit can be applied, and a similar growth rate of 0.0320 h-1 is determined. Online OUR data can be used to determine CHO growth rate, without having to do daily sampling and offline analyses.

CHO Batch Comparison

Fig. 3 shows viable cell density and online measured pH data in two batches of CHO cell culture. While cells grow, they produce lactate and the pH in the culture medium decreases. After approximately 125 h there is a metabolic shift and pH values start to increase again. If this shift does not occur, the maximum cell density and final product concentration will be lower than in an optimal culture run [2]. We use the online pH data for batch comparison and inoculum tests, to see if the CHO cells are suitable for further bioreactor runs. This way the SFR vario helps to evaluate the precultures, enhance reproducibility and avoid wasting time and resources on low performing bioreactor runs.

Backscattered Light Measurements

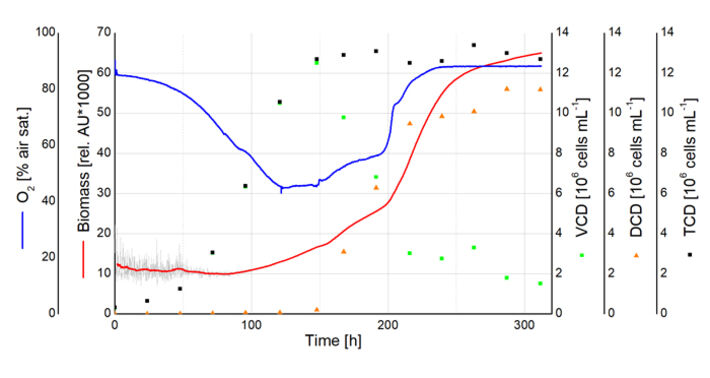

Fig. 4 shows online and offline determined process data of CHO DP-12 cell culture in an unbaffled shake flask. The unsmoothed backscattered light measurements (grey line) depict the strong signal noise at low cell densities. With increasing cell density, the signal-to-noise ratio decreases. While offline determined viable and dead cell densities as well as the online oxygen measurements indicate that at about 300 h of cultivation the death phase sets in, the backscattered light signal shows a steep increase. This is probably caused by the dead cells' changed cell surface. The backscattered light measurements correlate with dead cell density and might therefore be used as an indicator of viability.

Conclusion

The online data collected with the SFR vario can be used in different ways to analyse and characterize CHO cell lines. While the oxygen uptake rate can be used to determine growth rates, the pH curve can be used to compare batches and to choose suitable inoculum for larger scale cultivation. The online biomass signal might be used as an indicator for viability. The SFR vario not only gives a deeper insight into critical process parameters and helps to ensure the reproducibility in CHO cultivations it also reduces manpower for shake flask batch cultivations, as offline sampling and analyses are no more necessary.

Reference

[1] Wurm FM; Hacker D (2011). "First CHO genome". Nature Biotechnology. 29 (8): 718–20. doi:10.1038/nbt.1943. PMID 21822249

[2] Freund, N.W.; Croughan, M.S. A Simple Method to Reduce both Lactic Acid and Ammonium Production in Industrial Animal Cell Culture. Int. J. Mol. Sci. 2018, 19, 385.

This project was funded by the European Union within the EuroStars Framework (Project ID 11 795).