Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

CO2, Oxygen and Biomass Monitoring in E. coli Shake Flask Culture

Following Glucose-Glycerin Diauxie Online with the SFR vario

Helga Tietgens1, Gernot T. John2 and Katja Bettenbrock1

1Max Planck Institut für Dynamik komplexer technischer Systeme, Magdeburg, Germany

2PreSens Precision Sensing GmbH, Regensburg, Germany

Diauxic growth of E. coli in medium containing glycerin and glucose was monitored online with the SFR vario. The device measures biomass online via scattered light detection. Oxygen is determined with an optical sensor spot integrated in the shake flask and read out with SFR vario through the flask bottom. In addition to the oxygen sensor spot an optical CO2 sensor was integrated in the shake flask to evaluate the sensor performance for online dCO2 monitoring in microbial culture. Furthermore, pH, substrate concentrations and optical density were determined in offline measurements. The online readings showed the characteristic course of diauxic E. coli growth. Oxygen and CO2 measurements displayed reverse courses, as expected, indicating high oxygen consumption and simultaneous CO2 production during metabolic activity, while in phases of reduced or stopped activity the dissolved O2 content rose and the dCO2 level dropped. Online biomass measurements were in good accordance with offline measured OD values.

CO2 is an important parameter in microbial cultures as it can inhibit or stimulate growth under certain conditions. In this experiment, where E. coli diauxie was monitored online we focused in particular on dissolved CO2 and oxygen readings. The SFR vario by PreSens allows to measure oxygen, pH, and biomass optically inside an Erlenmeyer flask, and furthermore OUR can be calculated automatically with the reader's software. We evaluated an optical CO2 sensor spot (SP-CD1, PreSens) that was read out with the SFR vario device for its suitability in online monitoring of microbial cultures. Therefore, the sensor spot was integrated, like the oxygen sensor, in the shake flask and read out with the reader optics usually used for online pH monitoring. The measurement system allows such user specific adjustments and enables online monitoring of several parameters simultaneously. In addition to online measurement of biomass, oxygen and dCO2 we also determined pH, substrate concentrations and OD420 offline. Measuring several parameters - with all showing the same characteristics - enhanced the measurement security.

Materials & Methods

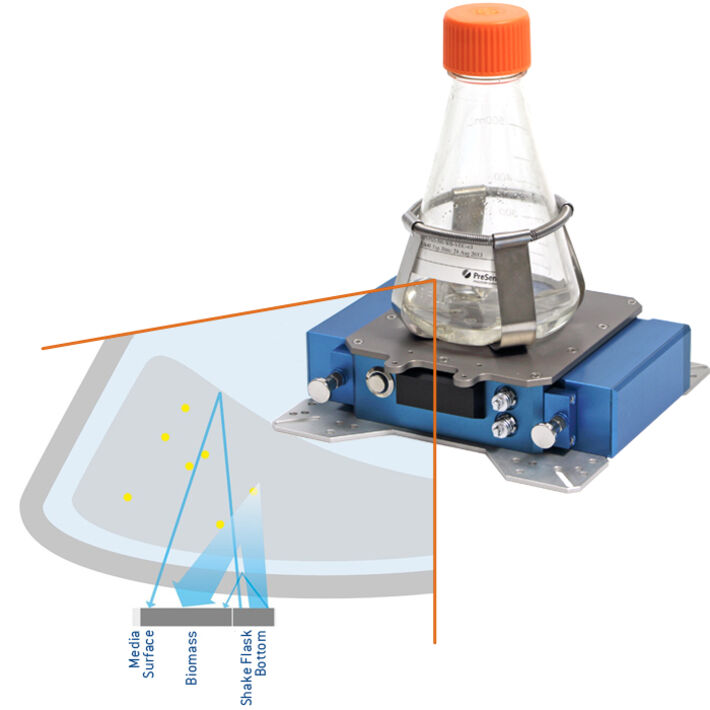

E. coli MG1655 were cultured in chemically defined medium according to Evans [1], with 0.15 % glucose and 1 % glycerin as sole carbon sources. The medium was buffered with phosphate buffer to pH 7. 500 mL plastic shake flasks with septum and a working volume of 200 mL were used for cultivation. The Erlenmeyer flasks were equipped with an oxygen sensor spot (SP-PSt3, PreSens) and additionally a CO2 sensor spot (SP-CD1, PreSens) was mounted at the flask bottom with an integration system (IS-SP, Fig. 1) supplied by the manufacturer. Both sensors were read out with the SFR vario through the flask bottom, while the reader also detected biomass via scattered light measurement (Fig. 2). The CO2 sensor was placed in the position where a pH sensor usually is integrated in the sensor flasks. This way the reader optics for pH monitoring could be used to read out the optical carbon dioxide sensor. The cultivation was incubated at 37 °C and 200 rpm. Online measurements with the SFR vario were supported by offline monitoring of pH, glucose and glycerin concentration, and determination of OD420.

Results

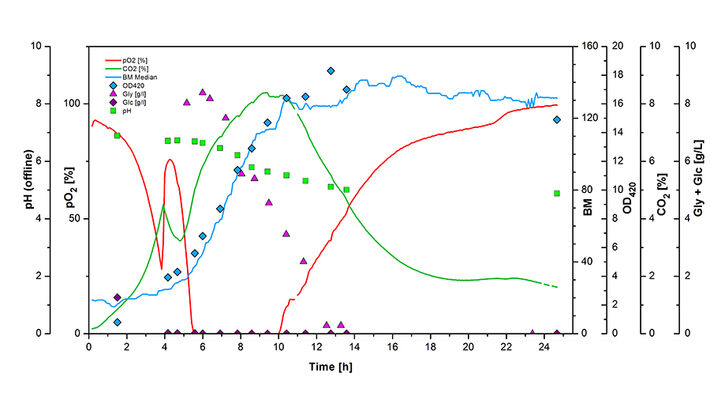

The graph (Fig. 3) shows the expected, characteristic course of diauxic E. coli growth. In the first growth phase (about 1 - 4 hours) glucose is used as carbon source, while glycerin is not metabolized. Biomass rises, while oxygen is consumed and CO2 produced during this phase. Oxygen consumption coupled with the simultaneous CO2 production indicate the aerobic metabolization of glucose. After about 4.5 h the dissolved oxygen level rises again temporarily while dissolved CO2 decreases. In this phase the preferred substrate glucose is completely consumed and the cells enter a short lag-phase. After a few minutes the microorganisms switch to metabolize glycerin and continue growing. Dissolved oxygen decreases with increasing cell numbers and drops down to zero level during this second growth phase. This is also displayed in a slower rise of online biomass and offline OD measurement values. Due to oxygen limitation E. coli cells can no longer grow with maximum growth rate on glycerin. The slowed down growth can be seen clearly in the bend of the dissolved CO2 curve. After about 10 h the glycerin is consumed and the culture enters stationary phase. Without substrate consumption the dissolved oxygen level rises back to 100 %, while CO2 slowly decreases.

In this experiment it is difficult to determine the growth rate based on the online biomass signal and OD values. However, the additionally measured CO2 values allow to see slowed down growth after an initial rapid growth phase on glycerin. It was expected that the dissolved CO2 concentration would drop towards zero level at the end of the cultivation period, however only a slow decrease down to about 1.8 % CO2 could be detected. This might be caused by cell lysis, and consumption of some of the cell parts by the other cells, so some CO2 is still produced during residual activity.

Conclusion

The evaluation of the CO2 sensor for microbial culture monitoring showed comprehensive results that were in accordance with the expected dissolved CO2 development during diauxic growth and indicated the activity levels of the cells very well. In combination with the oxygen measurements CO2 readings could be verified, as the measurement values of both parameters showed according tendencies. The simultaneous online monitoring of several parameters with the SFR vario enhanced the measurement security, as all recordings showed the same characteristics, allowing more precise assessment of the current culture status. It is also advantageous that the SFR vario system is easily adjustable to specific user requirements, and the read-out of the CO2 sensor instead of a pH sensor could be realized by very simple adaptations. The online monitoring device offers a save and time saving measurement tool for culture monitoring in shake flasks.

Reference:

[1] Evans et al. (1970), Chapter XIII, The Continuous Cultivation of Micro-organisms 2, Construction of a Chemostat, Meth Microbiol 2: 277 - 327