Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

María del Alamo and Ignacio Nevares

UVaMOX, E. T. S. Ingenierías Agrarias, Universidad de Valladolid, 34071 Palencia, Spain

Micro-oxygenation processes happening while storing wine in barrels give quality red wines the necessary final trait. Dissolved oxygen (DO) levels reached during the usual storage months are so low that measurement systems requirements become very high. There are measurement systems with detection limits at ppb (µg/L) based on electrochemical probes but they consume oxygen during the measuring process which is a problem as carrying out a dynamic measurement, i. e. in a fluid in motion, becomes necessary. Measurement of DO in wine flow has several disadvantages that can be solved but at the expenses of time and money. The optical measurement system Fibox 3 LCD trace allows to deal with the need of measurement in systems with low volume, at different atmospheric pressures, and the advantage of carrying it out in an inerted way.

DO measurement systems based on luminescence or fluorescence have been on the market for quite some time. Some of these equipments base their measurements on the signal amplitude while others do it on the signal delay. The latter shows the best performance, repetitivity, re-productivity and the most balancing measurement. But most equipments need a probe in which the luminescence or fluorescence substance is placed so that it gets in touch with the fluid to be measured. This probe is connected to the source of light and detector by an optical fiber. A breakthrough was brought about with a new equipment by PreSens GmbH that uses the very same measurement system but with a completely different approach. It is based on the brilliant idea of splitting up the sensor element and the rest of the equipment making the best use of the optical measurement systems. This solution enables to measure non-invasively and at reduced costs of those processes that do not need constant monitoring. It was possible to implement the use of PSt6 foils in wine aging systems with quite interesting results. The change from the traditional electrochemistry and luminescent systems to the new DO measurement system was fulfilled.

Monitoring during MOX Process

The measurements were taken in red wines during periods of a few days up to a 12 month period. A Fibox 3 LCD trace model was chosen to detect DO traces as it is portable and able to collect these data without a PC. Flat stainless sight glasses were adapted in storage systems used, barrels and tanks, to introduce the necessary spots to monitor DO. Flat stainless steel (AISI 316L) sight glass (DIN 11850 DN25) was used. Measuring with the MOX process can start once the sensor spot is installed in the sight glass of the tank (Fig. 3). Centering the polymer optical fiber (POF) is very essential. If it is carried out carefully, the measurement is very stable and offers very little variability. It is important to determine if room light affects the measurement.

The data logging results are (oxygen (µg/L, ppb)):

- valid N: 41

- mean: 6.829

- minimum: 6.0

- maximum: 9.0

- std. dev.: 0.629

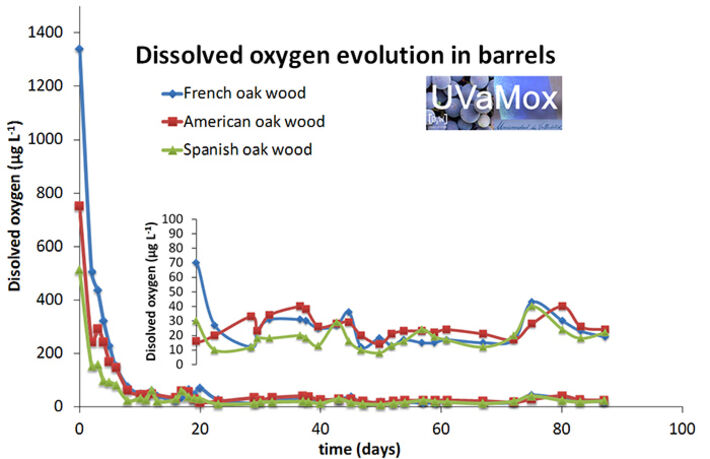

The device allows to monitor the natural micro-oxygenation of red wine (Fig. 4), specifically the evolution of DO during its storage in barrels. It is noted that the amount of oxygen is highest in wine aged in French oak barrel, followed by American oak and finally Spanish oak. This trend is not maintained during the aging, because, as shown in Fig. 4 from the 25 days of permanence in barrels, the DO levels present in the wine are very similar to the three barrels, with values very close to 20 ppb.

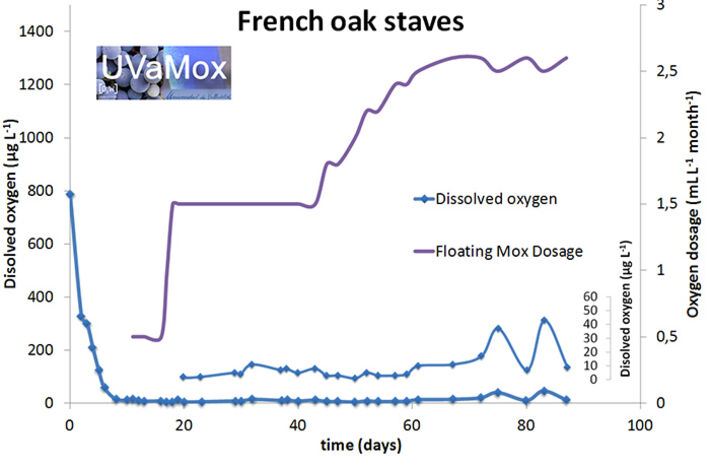

A follow-up of an aging process with staves and micro-oxygenation was done as well (Fig. 5). The measurement of the DO level in red wine allows you to control the process of MOX and thus makes an adaptive micro-oxygenation to maintain the desirable DO level using a floating oxygen dosage. This process allows maintaining a controlled level of DO next to 20 ppb, as go through in barrels. According to this data and its approach to measurement, it can be concluded that the Fibox 3 LCD trace is a valuable equipment to measure DO at very low levels since it is a non-intrusive system that avoids the manipulation of wine and, therefore, it rules out any possible interference in DO content.