Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Gas Input Measurements Using an Optical Oxygen Probe

Oxygen Input into the Liquid Phase of Three Different Reactor Concepts Measured with OXY-1 SMA trace

Natalie Mayer

Institute of Chemical Reaction Engineering, Friedrich-Alexander-University Erlangen-Nuremberg, Erlangen, Germany

The aim of this work was to show the performance of three different reactor concepts concerning the oxygen input into the liquid phase. For this purpose, water was aerated at 4.2 bar with synthetic air and the oxygen concentration measured at the reactor outlet. The results show a very good gas input in all three systems, as the theoretical maximum concentration of dissolved oxygen was almost reached. However, neither a significant difference between the two types of reactors nor of the two types of stirrers could be detected.

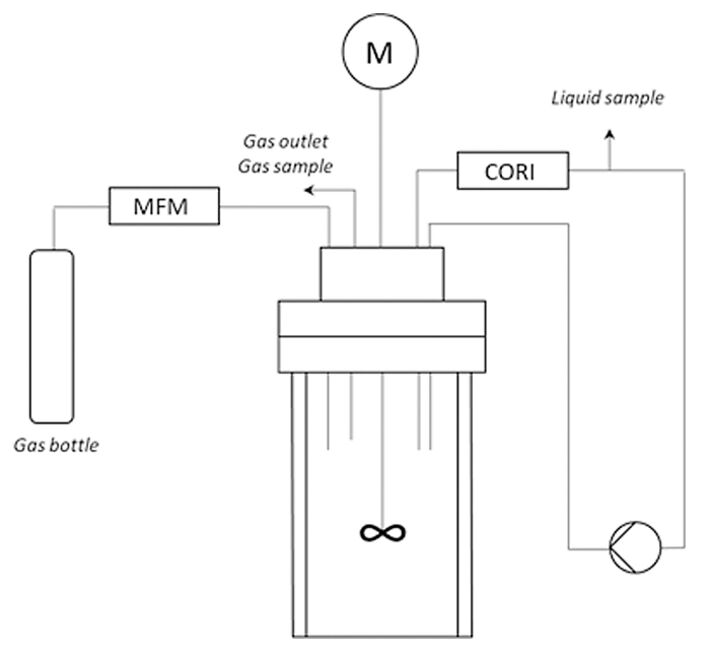

The here described investigation sought to judge the gas input in different reactor concepts of a mini-plant at the Friedrich-Alexander-University Erlangen-Nuremberg. The plant consists of the reactor as central part and a continuous external liquid circulation as schematically illustrated in Figure 1. To determine the amount of dissolved oxygen in the liquid phase a flow-through cell with an optical oxygen probe (FTM-PSt3) was installed directly at the reactor outlet. The data was transmitted to the PreSens Measurement Studio 2 software via the OXY-1 SMA trace oxygen meter. This optical oxygen measurement method provides a very precise and fast detection in this system, which will be crucial for pure oxygen aeration at high stirrer speeds. Furthermore, the special construction of the Hastelloy flow-through cell guarantees wide chemical resistance even at harsh conditions as well as safe application up to 15 bar.

Experimental Procedure

To allow for comparability between the systems and finally identify the best set-up, the measurement procedure was executed the same way in each experiment. First, water was filled into the reactor and then sufficiently flushed with nitrogen until an oxygen concentration below 2 ppm was reached. Afterwards, the system was pressurized with air at 4.2 bar and the oxygen concentration measured continuously until a plateau was obtained. The three systems compared in these experiments were a standard stirred tank reactor (system A) and a liquid phase Berty reactor, which was operated with two different stirrer types (system B and C), which were compared as well. In order to avoid disturbances by gas bubbles on the sensor the flow-through cell was placed in a vertical position and an additional pipe for degassing was installed directly before the cell. With this set-up stable data could be obtained.

Results

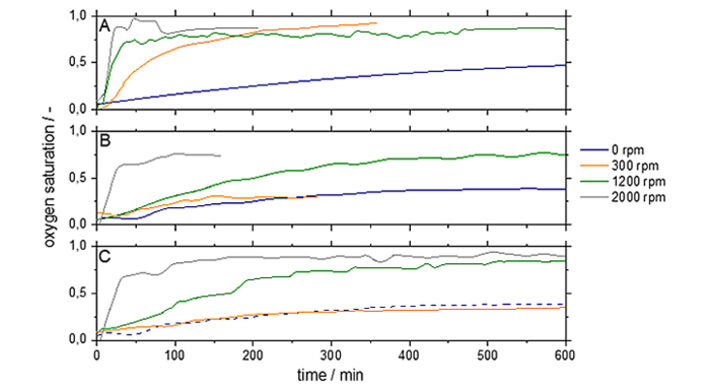

Figure 2 shows the relative oxygen concentration in the liquid phase over time. The absolute values were all referred to the theoretical oxygen saturation concentration at the given conditions. As presented in Figure 2 all reactor systems reach values of about 0.9 which equals 90 % of the maximum oxygen concentration. Thus, it appears that the gas input in all three systems is very good. As expected, all systems display better and faster gas input into the liquid phase with increasing stirrer speed. The direct comparison of all three systems shows in particular differences in the variation of stirrer speed. While the gas input at 300 rpm in systems B and C hardly reveals any notable oxygen solubility and almost no difference to the measurement without stirring, gas input in system A already reaches rather high values. Increasing the stirrer speed from 300 rpm to 1200 rpm, a further rise of dissolved oxygen in system A could be detected. Systems B and C also showed significant gas input under these conditions. The highest stirrer speed of 2000 rpm finally maximized the oxygen concentration in systems B and C so that the gas input reached a comparable level to system A where the last increase of rotation speed brought no further improvement.

Conclusion

The measurements show high oxygen input in all investigated systems but do not allow identifying significant advantages of either of the concepts. Only a shift of the rotation speed optimum could be distinguished. While the standard stirred-tank already reaches its maximum of dissolved oxygen concentration at 1200 rpm, the Berty-type reactor with both types of stirrers requires a speed of 2000 rpm to achieve comparable results. Moreover, a slight decrease of gas input duration could be determined in the stirred-tank system. However, as natural variations in the system with discontinuous circulation and therefore fluctuating gas input through the feed must be taken into account no definite conclusion can be made so far. Further experiments and more precise examinations could give more insight. We will now apply these results to real reactions, which will be carried out at the identified optimum conditions.