Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Online Monitoring of S. cerevisiae Culture with the SFR vario

New online biomass data is in very good accordance with offline measurements

Dylan Haskew1, Gernot T. John2, and Dogan Ornek1

1Upstream Process Development, FUJIFILM Diosynth Biotechnologies U. S. A., Inc., US

2PreSens Precision Sensing GmbH, Germany

In order to investigate a model process with Saccharomyces cerevisiae the new SFR vario shake flask reader was used to monitor O2, OUR, pH, and biomass online inside 2 L shake flasks. Two initial runs and one final model confirmation run were performed. The recorded biomass data was correlated with optical density (OD) by applying a linear calibration model. Online data gathered with the SFR vario system was then compared to offline measurements. Recordings taken in all three runs resulted in comparable data which also were in good accordance with offline measurements. The SFR vario enhances culture monitoring through easy handling and no need for sampling; moreover, it gives a more detailed view of culture performance.

The new SFR vario enables online monitoring of oxygen, pH, and biomass in shake flasks, and furthermore allows automatic oxygen uptake rate (OUR) calculation. The system is installed directly inside the shaker incubator and is controlled wirelessly via Bluetooth. Biomass is measured optically, and the reflectance values can be correlated to optical density (OD), cell dry weight (CDW) or cell concentration by creating a calibration model in a test run prior to the actual cultivation. The system is used with shake flasks having optical oxygen and pH sensors integrated at the bottom; these sensors are pre-calibrated by the manufacturer and the provided calibration files can simply be imported in the SFR vario software. We tested the performance of this device on a model process with S. cerevisiae comparing online results to offline pH and OD values gathered with classic sampling and measurement methods. Two initial runs and one model confirmation run were performed in 2 L shake flasks with integrated O2 and pH sensors at 28 °C, 225 rpm with a shaking diameter of 1.0 inch.

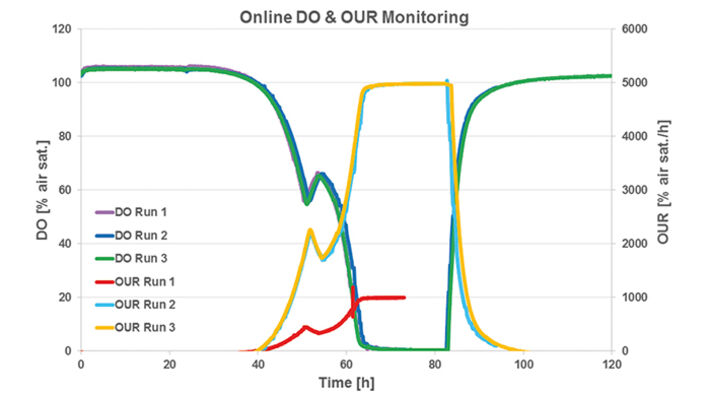

Oxygen Monitoring & OUR

The dissolved oxygen (DO) content was previously untracked in this model process. DO measurements with the SFR vario showed similar profiles for all three cultivation runs (Fig. 2). Cell growth led to a continuous decrease in oxygen levels inside the medium. When glucose was depleted S. cerevisiae switched to consume the previously produced ethanol. During this metabolic shift oxygen consumption is reduced, which is indicated by a small peak in the oxygen readings at 55 h of cultivation. In all three runs oxygen limitation set in after about 65 h. For automatic OUR calculation the kLa was entered in the software before initiating the run. kLa for Run 2 and 3 was 50 while Run 1 had a wrong kLa value of 10. The aberrant kLa of Run 1 caused discrepancies in OUR calculation when compared with Runs 2 and 3 (Fig. 2). These two cultures again showed similar profiles with increasing OUR till oxygen limitation was reached. The substrate change also showed in a small drop of OUR. Oxygen measurements and OUR calculation with the SFR vario delivered consistent results for all three culture runs, exept for the OUR of Run 1 caused by the wrong kLa value.

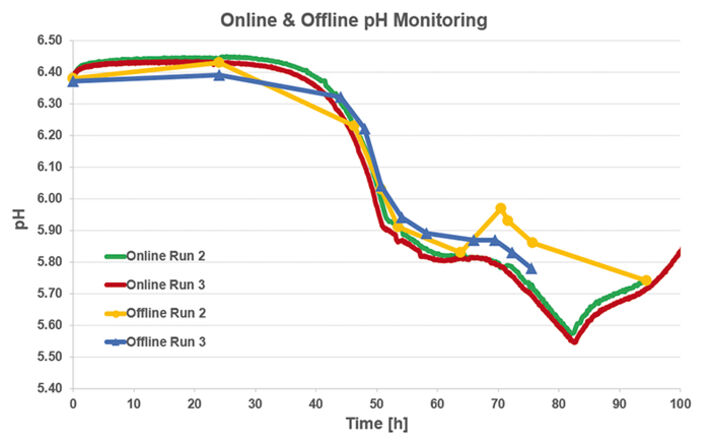

pH Measurements

We took offline pH measurements for comparison with the online measured SFR vario data. Due to incorrect placement of the flask above the optics, sensor read-out and with it pH online monitoring of Run 1 did not work out properly. The other two runs on the other hand delivered similar pH profiles (Fig. 3). In case of a significant offset of the measured pH and a known starting pH the SFR vario software offers a pH one point adjustment function, a one point calibration to adjust all following measurements. This function was not used in these experiments, and it turned out that the offline and online measured data were in good accordance. This proves that the pre-calibration of the pH sensor integrated in the shake flasks was accurate. The online readings of Run 2 and 3 correlated better than the offline measurement results among each other.

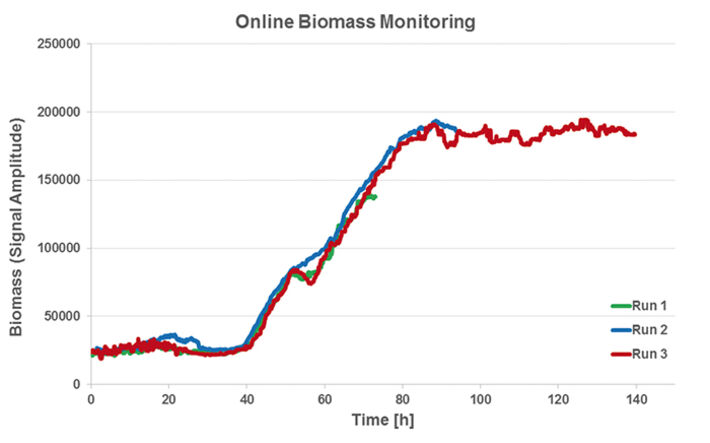

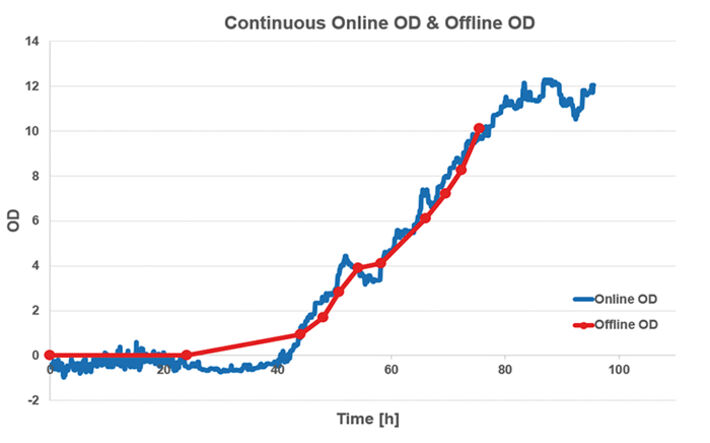

Biomass & OD Monitoring

We recorded the biomass reflectance values with the SFR vario and performed a trial run to take offline OD measurements for correlation with the online results. The biomass data showed comparable trends for all three runs (Fig. 4). The option to adjust the angle offset for biomass readings reduced the signal-to-noise ratio and measurement resolution could be improved. The online measured data again showed a small peak around 55 h, where a metabolic shift to consuming another substrate took place and growth briefly stagnated (as could also be seen in the oxygen measurements). We used a linear model with the formula y = a * x - b to correlate OD with the reflectance values, took more data and improved the measurement angle further. Comparing offline OD with the online OD values collected in two parallel cultures of Run 3 a strong model performance and good correlation of the data could be demonstrated (Fig. 5).

Conclusion

Our experiments with the SFR vario on a model process with S. cerevisiae demonstrated that this device delivers accurate data consistent with classic offline measurements. Previously untracked parameters could be recorded continuously, which resulted in a more detailed view of culture performance during the different phases. The online monitoring of multiple parameters with just one device delivers reproducible data with minimal work. Once the calibration model for biomass correlation is built, which is generated quickly and easily, no more sampling is necessary. The risk of contamination is reduced to a minimum. The included tracking of temperature and agitation is very convenient, as information about the exact culture conditions is saved with the data files and can later be referred to during analysis. The SFR vario proved to be an excellent tool for culture performance monitoring.