Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

pH Regulation for a Liver Cell Bioreactor

Prototype development with a chemical optical pH flow-through cell

Marco Decker

Fachhochschule für Technik und Wirtschaft Berlin (FHTW), Berlin

An important aspect of efficient liver cell bioreactors is the automated regulation of physio-chemical culture parameters. The present study describes the development of the first non-invasive pH regulation device for a perfusion bioreactor. The high performance of the system is based on a chemical optical flow-through cell for pH detection and its combination with precision mass-flow controllers for gas. The new controller allows long time stable and contamination free online pH regulation in complex bioreactor systems - an important technical contribution for future clinical applications.

Bioreactors in Clinical Medicine

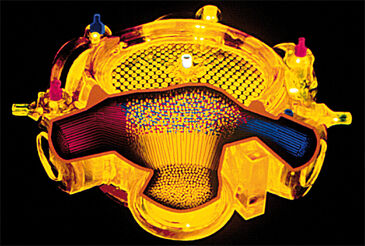

Transplantation medicine expects major progress from liver cell bioreactors (Figure 1) for clinical treatment of patients with acute liver failure. In an emergency case, liver cell bioreactors should support the patient`s liver function. In this way, the waiting period before transplantation of a suitable donor liver could be bridged. The liver takes part in important physiological tasks like protein biosynthesis, sugar metabolism, lipogenesis, excretion of bile acids or breakdown- and detoxification functions. For successful in-vitro culture of metabolically active liver cells, special culture systems are required. Ideal growth conditions concerning nutrient and oxygen supply as well as physico-chemical culture parameters have to be provided. Inside of the bioreactor a dense network of capillaries functions as both a growth substrate for cells as well as a supporting system for nutrients. With such bioreactor systems liver cells can be maintained already in stable long-term culture. For further improvement of its capability and reliability, an automated and transportable pH regulation technique has now been developed. As distinctive feature of the implemented control circuit a non-invasive measuring device for pH on-line detection is employed. Based on a refined optosensoric measuring technique the flow-through cell pH detector of PreSens allows a contamination free pH regulation within the bioreactor.

Design of the pH Control Circuit

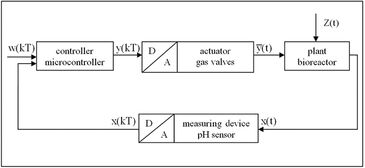

The optimal pH for liver cell culture lies between pH 7.3 - 7.45. In order to achieve a permanently stable pH value within the bioreactor, the amount of added CO2 must be continuously adapted to the current pH. Besides the pH flow-through cell, the underlying control circuit (Figure 2) consists of an actuator for the gas mixture as well as the unit for computing tasks - the real controller. As a liver cell culture can tolerate only minimal deviations of the pH, a PI (proportional-integral) controller was chosen. This controller type is exactly adaptable to the specific requirements of the bioreactor system. For the cells in the bioreactor, PI controlling is more suited than two-point regulation, since no permanent shifts of the controlled condition take place. The pH value of the cell culture medium is monitored non-invasively from the flow-through sensor and transmitted to the controller. The implemented PI control algorithm then calculates the manipulated variable. The controller sends these data to the mass-flow valves, which generate a constant gas mixture flowing through the capillaries of the bioreactor.

Functional Characterization of the pH Control Circuit

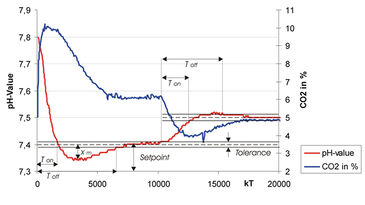

The characteristics of the new PI control circuit can be proven by means of induced disturbances. High metabolic cell activity within the bioreactor is simulated by adding citric acid (12 and 25 mg/ml, respectively) to the culture medium. The monitored pH values and the respective compensation by CO2 reveal the following characteristics of the control circuit (Figure 3). After initial saltation-like change of the pH from stationary value 7.4 to 7.2 (trial 1) about 41 minutes pass by until again achieving the command value. It takes about 2h 45min until full stabilization. The overshooting is in a 0.03 pH units range. In trial 2, the pH value again decreased saltation-like from pH 7.4 to pH 6.92. The set value was achieved again after 26 minutes. The maximum overshoot was 0.04 pH units. Complete system stabilization occurred after 2 h 50 min.

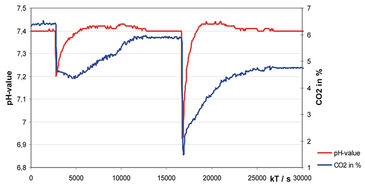

Although a fixed set-point control circuit was realized in the present study, the control performance is remarkable even at other pH value set-points. Figure 4 displays the characteristics of the control variable for two different set-point shifts: pH 7.8 to 7.4 (a) and pH 7.4 to 7.5 (b). From the data, important quality features of the time response can be derived like control deviation, rise- and transient time as well as the transient overshoot. In the first case, the transient overshoot was at 15 %, with a rise time of 1,600 seconds and a transient time of 6,400 seconds.

Better than in a two-step control device (details in original version), the control variable achieves the pH value of 7.4 and keeps it also constant. Like in the first set-point shifts, the pH value achieves the proposed second value of 7.5. There, it is also maintained constantly. The transient overshoot is about 20 %, rise- and transient time 1,800 seconds and 4,800 seconds, respectively. The study reveals that also other pH values than the prefixed one of pH 7.3 - 7.45 may be selected.

Striking Perspectives

This prototype of a non-invasive pH regulation for bioreactors is an important contribution to further optimization of the methodical basis for clinical applications in liver disease and cell transplantation. The integrated opto-sensoric pH measuring technology of PreSens copes in a particular way with the high demands in measuring precision and contamination-free long term stability. The clinical test of the pH controlled perfusion bioreactor moves closer.

Application note adapted from

Diploma Thesis of Mr. Marco Decker, Fachhochschule für Technik und Wirtschaft Berlin (FHTW), Berlin, Germany (2007).