Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Quantification of Oxygen Consumption of Meat-Spoiling Microorganisms below 30 % CO2 / 70 % O2 Atmosphere

Measurements in a Simulated Meat Packaging Environment with Optical Oxygen Sensor Spots SP-PSt3

Sandra Kolbek

Chair of Technical Microbiology, Technical University of Munich, Germany

In order for meat products to maintain their red color, beef and pork are packaged under a modified atmosphere. Mainly, a protective gas atmosphere consisting of 30 % CO2 and 70 % O2 is used. The high oxygen content in the protective atmosphere prevents the red myoglobin in the blood from oxidizing to the brownish metmyoglobin.

In previous work at the Chair of Technical Microbiology, it was found, that the oxygen content in meat packaging with protective atmosphere was constantly decreasing over a storage period of several days in continuous cooling. This resulted in an undesireable color change of the meat product. In addition, the meat's predominant microbiota changed depending on the oxygen content in the packaging. The resulting question was: Which meat-spoiling microorganisms are able to consume oxygen and thus attribute to the decrease of oxygen content in the packaging? Moreover, how large is the contribution of these microorganisms to the oxygen consumption in the meat packaging?

Material & Methods

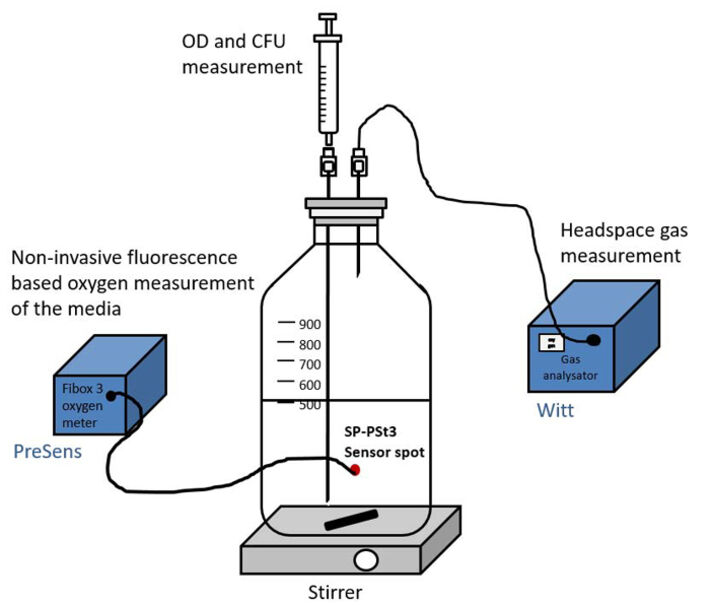

A model system was developed in 1 L high-pressure bottles, which simulates the conditions on real meat. The bottles were half filled with a meat-like medium and the headspace was replaced with the protective atmosphere of 30 % CO2 and 70 % O2. The bottles could be sealed gas-tight with a butyl stopper. Thus, the fermentation medium could be compared to real meat and the headspace compared to the protective atmosphere in meat packaging. With two cannulas the headspace as well as the bacterial growth could be recorded. An oxygen sensor spot SP-PSt3 was mounted to the inside wall of each bottle at height of the culture medium. Thus, the dissolved oxygen content inside the medium could be monitored non-invasively through the bottle wall with a Fibox 3 LCD trace oxygen meter. The bottles were inoculated with the five meat-spoiling microorganisms Brochothrix thermosphacta, Carnobacterium divergens, Carnobacterium maltaromaticum, Leuconostoc gelidum subsp. gelidum and Leuconostoc gelidum subsp. gasicomitatum.

Results & Evaluation

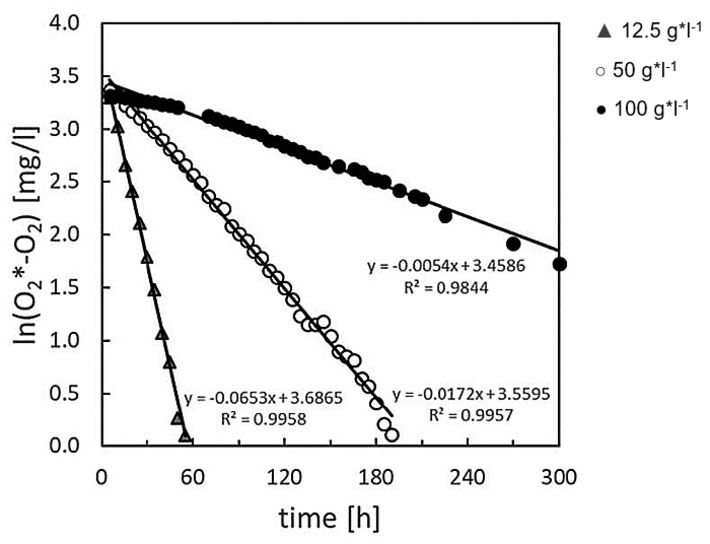

All species were able to utilize the dissolved oxygen in the medium. The maximum as well as the average oxygen uptake rate (OUR) was calculated for all species. First of all, the diffusion constant kLa for the three fermentation media (12.5 g/L meat extract, 50 g/L meat extract and 100 g/L meat extract) was determined with the gassing out method.

Subsequently, the average as well as the maximum oxygen uptake rate (OUR) was calculated with the formula:

OUR = kLa • ([O2]* - [O2]) - d[O2] / dt

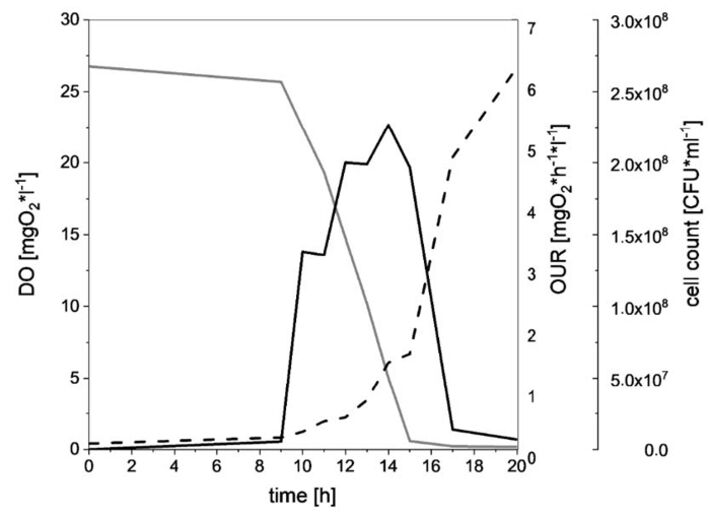

The following relationship between dissolved oxygen (DO), OUR and cell count (CFU) in the medium could be detected:

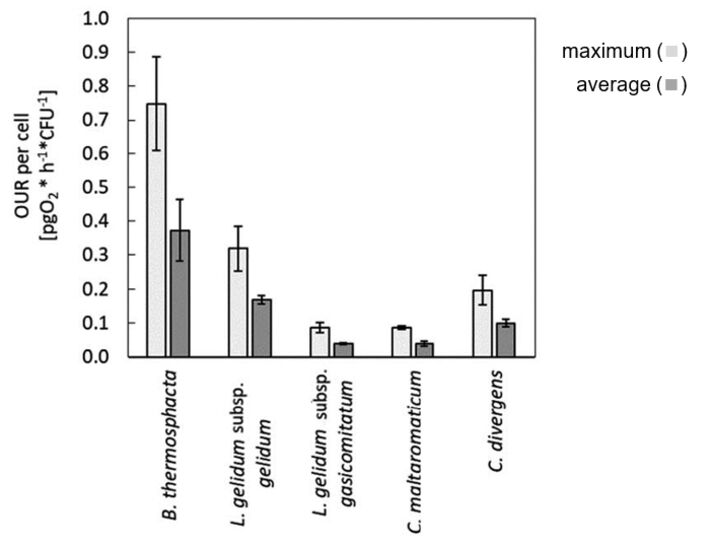

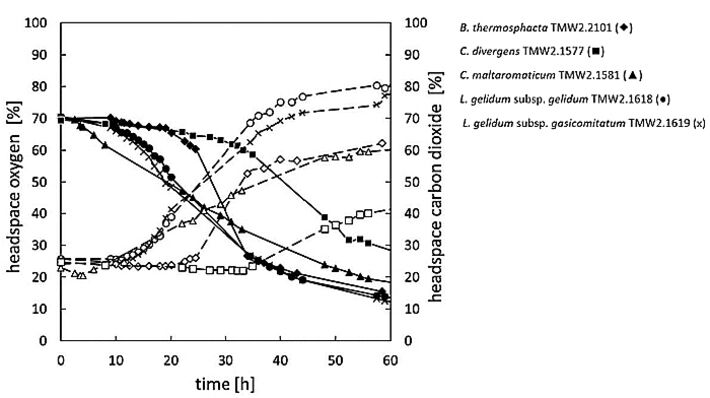

The species B. thermosphacta showed a significantly higher oxygen uptake rate per cell compared to the other four lactic acid bacteria. Looking at the headspace measurements in the bottles, a clear decrease in oxygen content for all species could be determined.

Calculations of total headspace oxygen consumption over the 60 hour period also showed a significantly higher oxygen uptake rate per cell of the species B. thermosphacta compared to the other lactic acid bacteria.

Conclusion

These results prove that all five meat-spoiling microorganisms in this study contribute to the decrease in oxygen content in meat packages. Furthermore, it could be shown that B. thermosphacta makes a higher contribution to the oxygen consumption in meat packages than the other examined species. The non-invasive optical measurement principle of the SP-PSt3 sensor spots was a great advantage in these experiments as they allowed measuring the medium oxygen content through the bottle wall without having to modify the closed, gas-tight system.