Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Validation Study of the Optrode Dual™

Oxygen and pH Measurements in a Single-Use Bioreactor with Integrated Optical Sensors Using a Conventional Controller

Stephan Kaiser & Dieter Eibl

Institute for Biotechnology, Department of Life Sciences and Facility Management, Zurich University of Applied Sciences, Switzerland

The Optrode Dual™ converts measurement data of optical sensors into electrochemical signals (ECS) which can be transferred to controller units for bioreactors. The user can record data for pH and dissolved oxygen in single-use bioreactors with integrated chemical optical sensors. In this validation study the basic functionality in a model system is characterized. It successfully connects systems from different manufacturers. In the tests described here the transmitter was applied for measurements in a cultivation bag with integrated sensors where pH and DO profiles were adjusted. The online measured pH values were compared with external measurements. Accurate and correct functioning of the Optrode Dual™ prototype could be verified.

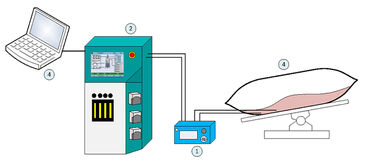

Chemical optical sensors allow non-invasive monitoring of oxygen and pH in bioreactors. Traditionally, most controller units are designed to work with electrochemical sensors only. This is why PreSens developed the Optrode Dual™. This transmitter converts the reading of optical sensors into electrochemical signals (ECS). It can be connected to the analog inputs of conventional controllers and makes it possible to transfer and record pH and oxygen readings of optical sensors integrated in single-use bioreactors using the existing equipment in the lab. The Optrode Dual™ allows connecting systems from different manufacturers as shown in the following experiment. The optical sensors mounted in a cultivation bag were connected to the Optrode Dual™ via polymer optical fiber and data for pH and dissolved oxygen readings were transferred to the ez-control® by Applikon (Fig. 1). The Optrode Dual™ can be easily connected and provides fail-safe calibration for the optical sensors via 2D barcode control. In the following tests pH and DO profiles were adjusted and measurement data recorded to evaluate the functionality of the new device. Online measured pH values were compared to offline measurements to check whether the pH readings are correct.

Materials & Methods

The Optrode Dual™ prototype was connected to the ez-control® (Applikon, Netherlands) which was connected to a PC via Ethernet cable for data recording. Data collection of pH and DO readings was realized with the BioXpert software (version 2.93.122b2), the sampling interval set to 1 minute. Calibration of the optical sensors was done with the Optrode Dual™ by barcode control. Specific barcodes for calibration were generated with a special software provided by PreSens. The cultivation bag with integrated sensors was used at maximum working volume of 10 L, and placed on a BioWave 20 SPS platform (Wave Biotech, Switzerland) with a movement rate of 30 rpm and an angle of 7°. Phosphate buffered saline (PBS) served as a model medium, which was conditioned to a constant temperature of 37 °C. Air was introduced with a constant stream of 0.5 L min-1 (0.05 vvm) by the ez-control® unit. For adjusting the pH and DO profiles air supply was cut and 0.1 L min-1 CO2 or 0.4 L min-1 N2 were streamed into the bioreactor. When a pH value of 6.4 and DO concentration of 10 % was reached air was introduced in the bag again.

Handling the Optrode Dual™

The functionality of the Optrode Dual™ for measuring pH and DO with optical sensors integrated in a cultivation bag was investigated. With the supplied cables the transmitter could be easily connected to the controller. Due to its compact size the device doesn´t require much space. Calibration was done with barcodes provided by PreSens or with generated codes. The barcodes have to be placed in a certain position before the barcode reader of the Optrode Dual™, which required some practice. Barcodes printed in a bigger format (4 x 4 cm) seemed to work better for the reader.

Measurement Results for pH Profiles

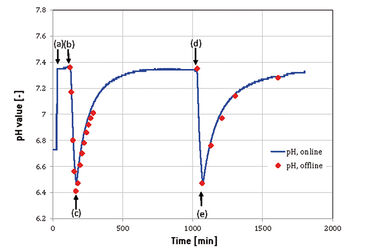

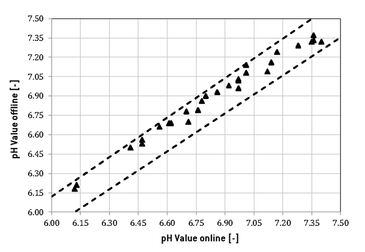

Figure 2 shows a typical pH profile when adding CO2 with 0.2 L min-1 to the bioreactor. In total 5 repetitions were performed but for better clarity only the first two cycles are displayed in the graph. In the first cycle more samples for offline pH measurement were taken than in the second cycle. Throughout the test online and offline pH values were in good accordance. At the beginning the pH was calibrated to a value of 7.35 which is obvious in the dramatic increase of pH at the beginning. With continuous CO2 addition the pH value dropped to 6.47 within 35 minutes. By cutting the CO2 supply and streaming air with 0.5 L min-1 into the bioreactor the pH value increased to the initial value within 500 minutes. The relative deviation between online and offline measured pH values was below 2 % so both methods showed very good accordance (see Fig. 3).

Measurement Results for DO Profiles

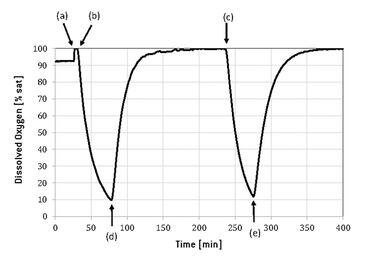

Figure 4 shows a typical DO profile when introducing N2 periodically in the bioreactor. Again 5 repetitions of N2 addition had been made but only the first two cycles are shown in the graph for better clarity. At first, the DO sensor was calibrated to 100 % in a one-point calibration, as can be seen in the graph. Shortly afterwards the air supply was cut and nitrogen streamed into the bioreactor, which caused a decrease in dissolved oxygen concentration. When the DO level reached 10 %, air was streamed into the bioreactor again. It took about 90 minutes until the model medium was completely saturated. This cycle could be reproduced in the following repetitions. The times needed to reach the upper and lower DO level (10 % and 100 %) varied only in a range of 3 minutes, with the sampling interval set to 1 minute. Small variations might be caused by fluctuations in the gas supply which was realized with rotameters. Reference measurements with another system were not performed during this test.

Conclusion

Functioning of the Optrode Dual™ in combination with a cultivation bag with integrated optical sensors and a conventional controller has been evaluated. It delivered correct measurements when connected to the optical sensors integrated in the bag. During the whole testing period no functional or technical problems of the transmitter could be determined. Connecting the compact device only takes a few minutes and enables to assemble a new monitoring set-up out of equipment by different manufacturers. The Optrode Dual™ has proven to be a very useful tool for process monitoring in single-use bioreactors.