Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Why It Is Important to Measure Different Parameters Online in Shake Flasks

SFR vario Measures O2, OUR, pH and Biomass Online

R. W. Maschke1, G. T. John2, and D. Eibl1

1 ZHAW Zurich University of Applied Sciences, School of Life Sciences and Facility Management, Wädenswil, Switzerland

2PreSens Precision Sensing GmbH, Regensburg, Germany

Optical sensors enable monitoring and controlling important culture parameters even at shake flask scale. In this short report we show an example of multiparameter monitoring with SFR vario in S. cerevisiae culture, and how different sensors deliver most conclusive information in different culture phases.

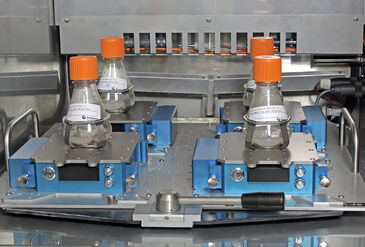

SFR vario

The SFR vario is an optical monitoring unit for shake flasks which allows measuring several parameters simultaneously. Optical oxygen, pH and CO2 sensor spots are integrated in the shake flask and can then be read out through the transparent flask bottom while biomass is measured via backscattered light measurement. Both measurement methods are completely non-invasive, so there is no need for sampling or any other interference during the shaking process, while data is available online. Furthermore, OUR is automatically calculated from the oxygen measurements with the SFR vario software PreSens Flasks Studio.

The Multiparameter Approach

In the following, we show an example of multisensor monitoring in S. cerevisiae culture to illustrate the importance of not relying only on the measurement of one parameter. In the different culture phases, different sensors provide the best results and thus enable a reliable overall picture.

Multi-Sensor Monitoring in S. cerevisiae Culture

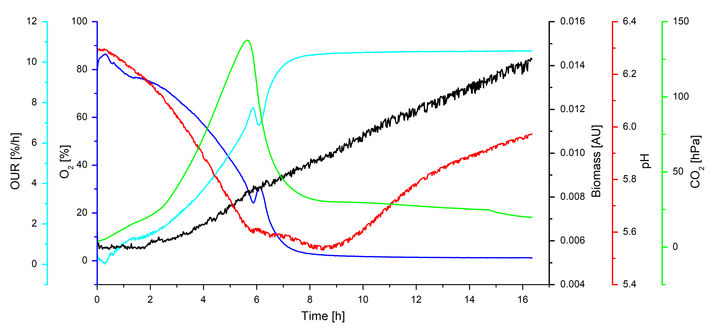

Figure 2 shows online O2, OUR, pH, CO2 and biomass measurements of a S. cerevisiae strain in YPD medium. The culture was performed in 500 mL shake flasks with 100 mL filling volume, at 30 °C and 180 rpm (50 mm shaking diameter).

During the first 6 hours of cultivation the oxygen sensor signal shows continuous, increasing oxygen consumption – a clear signal indicating the exponential culture growth. Even the short drop of OUR at hour 6 can easily be recognized. It is caused by a metabolic switch from ethanol production to ethanol consumption when the primary carbon source (glucose) becomes limiting (see CO2 sensor). Later oxygen becomes limiting and the O2 level remains zero, i.e. has no more information about the dynamic of the system.

The backscattered light measurements cannot give conclusive information in the first 2 hours due to the initial low cell density. However, it continues to provide information about the biomass formation when the oxygen sensor remains at 0% due to the limiting oxygen supply.

The (optional) CO2 sensor shows an increase in carbon dioxide levels during ethanol production. After the metabolic switch CO2 production then decreases, which is also reflected in a slower decrease in pH, as less CO2 is present in the culture broth. After 7 hours, when the oxygen consumption rate is at a maximum the O2 signal gives no further useful information. At this culture stage the signal of CO2 and pH sensors deliver more conclusive information and the rising pH values after 9 hours indicate ongoing growth. During this period the biomass signal now clearly shows the continuously increasing growth curve.

Conclusion

The SFR vario offers monitoring of several independently measured parameters and delivers the full picture. The signals can validate each other to have higher bioprocess security and more reliable and reproducible production. It gives uninterrupted conclusive information for the whole culture period. This makes it the ideal tool for process development at shake flask scale.

Reference

More advanced data analysis can be found at Maschke et. al. Improved Time Resolved KPI and Strain Characterization of Multiple Hosts in Shake Flasks Using Advanced Online Analytics and Data Science. Bioengineering 2022, 9, 339. https://doi.org/10.3390/bioengineering9080339