Sensor Engineering Saves Both Time and Money

February 29, 2012High-throughput methods based on customized sensor engineering by PreSens allow efficient process development by miniaturization and parallelization in Biotechnology as well as the chemical and pharmaceutical industry.

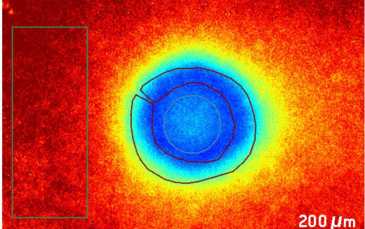

The challenges companies have to face - especially in the field of bioprocess control, biological and environmental research, pharmacy, medical devices or food and beverage - demand more and more customized, but still affordable solutions. These companies operate on a market characterized by brief innovation cycles, short-lived technologies and constantly changing customer requirements. These are some of the reasons why it is so important to find a budget-friendly answer to the demands of the market. PreSens focuses strongly on modularity while developing customized sensor engineering, which might allow its customers being a step ahead. What is sensor engineering in a specific case? It is e. g. part of an easy-to-use and cost-effective method to determine oxygen permeability of important synthetic materials; it is a module that helps to scale-down production processes in milliliter volumes in biotechnology while monitoring dissolved oxygen and pH by a high-troughput method based on miniaturization and parallelization; or it helps a pharmaceutical company to monitor pH simultaneously in a large number of cell culture tubes.

In the last decade, PreSens Precision Sensing GmbH in Regensburg, Germany, developed together with its partners in research and its customers demand-orientated products for measuring oxygen, pH and carbon dioxide.

Contact:

Christina Schlauderer

Communications

PreSens Precision Sensing GmbH

Phone: +49 941 94 27 21 09

E-Mail: christina.schlauderer@presens.de