Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Evaluation of an Optical O2 Probe and Sensor Spots for Long-Term Measurements in Stirred-Tank Bioreactors

Mammalian Cell Culture Monitoring with OXYPro® and Sensor Spots SP-PSt3

Melissa Hill1, Greg Laslo1, Marcelo Kern1, Sayantan Bose1, Christian Krause2

1GlaxoSmithKline, King of Prussia, PA, USA

2PreSens Precision Sensing GmbH, Regensburg, Germany

We used PreSens optical sensor spots and the OXYPro® oxygen probe for cell culture monitoring in a stirred-tank bioreactor. The optical measurements were compared to data determined with a controlling and a monitoring DO probe. Several oxygen sensor spots were attached to the bioreactor's side walls. The OXYPro® steel probe was integrated via a standard port from the top. Measurements during a 15-day mammalian cell culture showed that the probe, as well as the sensor spots, trended well with the reference probes. No drift could be detected in the optical oxygen measurements. However, the OXYPro® as well as the reference probe were affected by O2 sparges. the sensor spots by PreSens seemed the best oxygen measurement solution in this set-up.

Monitoring and controlling the dissolved oxygen (DO) content in mammalian cell culture is imperative to ensure stable cell growth and reproducibility. Precise oxygen sensors are needed that can be implemented in bioreactors and deliver reliable data over long time periods. In this study, we tested different optical sensor designs by PreSens - sensor spots and a steel probe - for their suitability to monitor and control DO in a stirred-tank bioreactor. Several oxygen sensor spots were attached to the glass wall of the bioreactor. They were read out from the outside via a polymer optical fiber. While one sensor spot was used for continuous measurements, the other spots were only periodically read out to determine spot-to-spot variability and signal drift. The optical steel probe OXYPro® was inserted through the bioreactor lid via standard port. All electro-optical components of this probe are integrated in the steel housing, and it can be connected to a controller or PC via cable connection. The non-invasive sensor spots are suitable for integration in autoclavable glass bioreactors, while the OXYPro® is also suitable for use in steel fermenters. Optical pH sensor spots and a novel pH steel probe by PreSens were also evaluated in these tests and the results are described in a separate application note. In future studies, the optical sensors will also be tested when connected to a controller.

Material & Methods

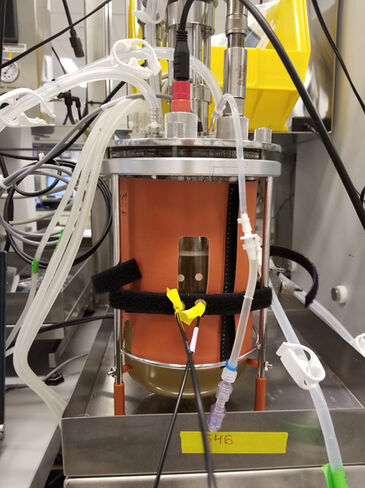

The optical oxygen sensor spots (SP-PSt3) were attached to the inner bioreactor wall of a 3 L glass reactor. The bioreactor was autoclaved prior to inoculation with a CHO cell line. A hole was cut in the bioreactor heat jacket at the spot position so they could be read out via polymer optical fiber from the outside. An adapter for round containers (ARC) was used to hold the optical fiber opposite one spot for continuous read-out. The other sensor spots were periodically checked to determine spot-to-spot variability, drift and the effect of photobleaching over a period of 15 days. the sensor spots were read out with OXY-1 SMA oxygen meters which were controlled with the PreSens Measurement Studio 2 software. The OXYPro® steel probe was inserted in the bioreactor via a standard port in the lid and was positioned as far away from the oxygen sparger as possible (Fig. 1). The DO setpoint was 50 ± 10 % on the Applikon EZ Controller system. A Mettler-Toledo optical probe was used for DO control. Continuous oxygen measurements were performed at time intervals of 3 seconds over 15 days.

Results

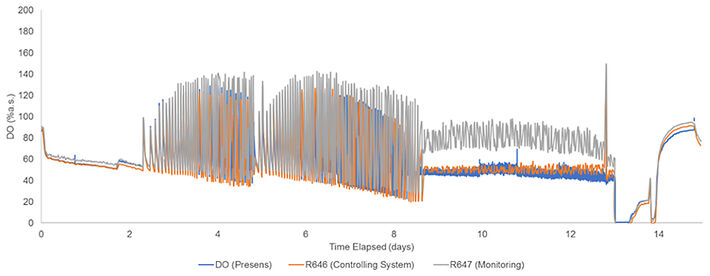

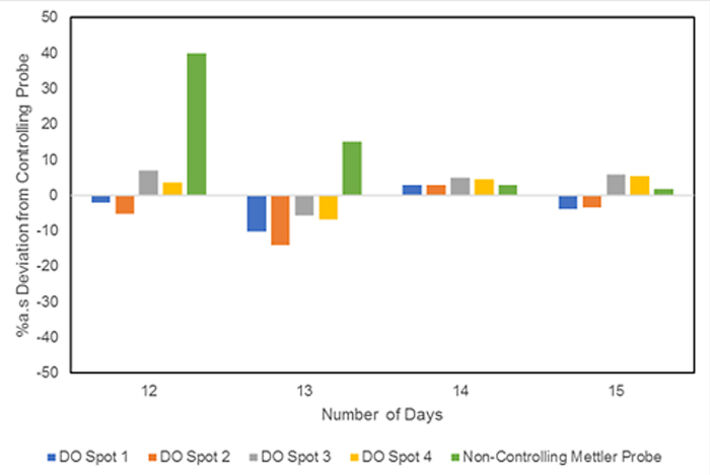

Figure 2 shows the performance of the optical sensor spots during 15 days of culture monitoring in comparison to a controlling and non-controlling reference probe. The sensor spots trended well with the controlling probe (see Fig. 3). While the optical Mettler-Toledo probes struggled with the DO control, the spot measurements were not affected as significantly. During the whole measurement period no drift could be detected in the sensor spot data. The rapid fluctuation began on day 3 after perfusion for the system took place. The PreSens DO spot did not deviate, even after the reactor reached a peak cell density of 40 million cells/mL.

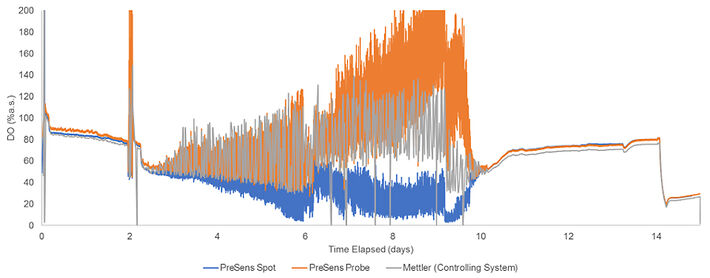

The OXYPro® probe also trended with the controlling probe, except when the O2 sparge rate was high, as shown in Figure 4. Despite placing the PreSens probe as far as possible from the sparger, it seemed affected by the air bubbles as did the controlling probe. PreSens also offers a beveled sensor cap that can be screwed to the probe body and might reduce the effect of air bubbles on the oxygen readings; however, this was not tested in our experiments. Compared to the probes, the sensor spots in the bioreactor generated more stable measurements and were not so severely affected by the O2 sparges. The sensor spots seemed to be the most trustworthy DO sensors in this set-up.

Conclusion

Our experiments demonstrated that both the optical sensor spots and the OXYPro® can be used for oxygen monitoring in stirred-tank bioreactors. We detected no signal drift during the 15-day test period, which shows the long-term stability of these sensors. While the oxygen steel probes that were inserted from the top of the bioreactor were affected by the air bubbles during O2 sparges, the sensor spot measurements showed less fluctuation. In this bioreactor set-up, the sensor spots seem to be the most reliable measurement solution for oxygen monitoring. Further tests will be conducted to test the different optical sensors connected to a controller.

Acknowledgement

The project leading to this application has received funding from the Innovative Medicines Initiative 2 Joint Undertaking under Grant Agreement n°777397. This Joint Undertaking receives the support from the European Union’s Horizon 2020 research and innovation program and EFPIA.

Disclaimer

The communication reflects the author's view and neither IMI nor the European Union, EFPIA, or any Associated Partners are responsible for any use that may be made of the information contained therein.