Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Autoclavable Sensor for Most Precise Oxygen Measurements

Oxygen Sensor Spot SP-PSt3-YAU

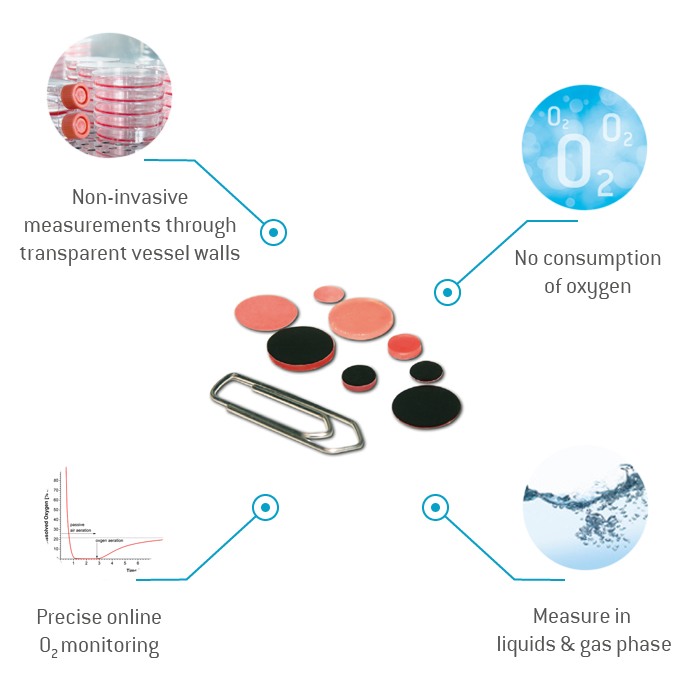

Sensor spots are the most versatile version of non-invasive optical oxygen sensors. They can be attached to the inner surface of any transparent glass or plastic vessel like e. g. shake and spinner flasks, tubes, Petri dishes or cultivation bags. Oxygen is measured non-invasively and non-destructively through the transparent vessel wall. The SP-PSt3-YAU has a measurement range of 0 – 100 % oxygen in dissolved or gaseous phase. The oxygen sensitive coating is immobilized on a 1 mm glass support, which can be autoclaved (+ 130 °C, 1.5 atm).

- Contactless measurements through the vessel wall

- No consumption of oxygen

- Signal independent of flow velocity

- Measures oxygen in liquids as well as in gas phase

- Autoclavable

Applications

Bioprocess Development: Oxygen Monitoring in Shake Flasks

O2 supply is one of the major issues in the cultivation of aerobic organisms. Shake flask cultures are widely applied in academic and industrial bioprocess development. As adequate methods for real monitoring of dissolved oxygen were missing, sufficient O2 supply is usually assumed. The non-invasive oxygen sensors in shake flasks now ensure oxygen supply and give new insights into metabolic activity.

Respiration & Photosynthesis: Oxygen Monitoring in Glass Vials

Determination of respiratory activity is often performed for water organisms such as invertebrates, larval stages or eggs, but also for bacteria, cell cultures, yeasts or fungi. For algae measurement of photosynthetic activity is of great interest. Using our 20 mL SensorVial with an integrated sensor stripe oxygen can be measured simultaneously in the liquid sample and in the headspace. Autoclavable SensorVials for stirred and non-stirred applications are available.

Technical

| Specifications | Gaseous & Dissolved O2 | Dissolved O2 |

|---|---|---|

| *after two-point calibration as described in the manual | ||

| Measurement range | 0 – 100 % O2 0 – 1000 hPa | 0 – 45 mg/L 0 – 1400 µmol/L |

| Limit of detection | 0.03 % oxygen | 15 ppb |

| Resolution | ± 0.01 % O2 at 0.21 % O2 | ± 0.004 mg/L at 0.091 mg/L |

| Accuracy* | ± 0.4 % O2 at 20.9 % O2 ± 0.05 % O2 at 0.2 % O2 | |

| Drift | < 0.03 % O2 within 30 days (sampling interval of 1 min. / at 0% oxygen) | |

| Measurement temperature range | from 0 to + 50 °C | |

| Response time (t90) | < 6 sec. | < 40 sec. |

| Properties | ||

| Compatibility | Aqueous solutions, ethanol, methanol | |

| No cross-sensitivity | pH 1 – 14 | |

| Cross-sensitivity | Organic solvents, such as acetone, toluene, chloroform or methylene chloride Chlorine gas | |

| Sterilization procedure | Steam sterilization Ethylene oxide (EtO) Gamma irradiation | |

| Cleaning procedure | Cleaning in place (CIP, 2 % NaOH, + 80 °C, + 176 °F) 3 % H2O2 Acidic agents (HCl, H2SO4), max. 4 – 5 % | |

| Calibration | Two-point calibration with oxygen-free environment (nitrogen, sodium sulfite) and air-saturated environment | |

| Storage stability | 60 months provided the sensor material is stored in the dark | |

Related products

Resources

Publications

FAQs

Manuals

Brochures

Software

PreSens Datamanager version 2.0.0.57 - Windows XP/Vista/7/8

PreSens Oxygen Calculator version 3.1.1 - Windows 7/8/10