Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Online Monitoring of C. glutamicum Culture in Ultra Yield® Flasks

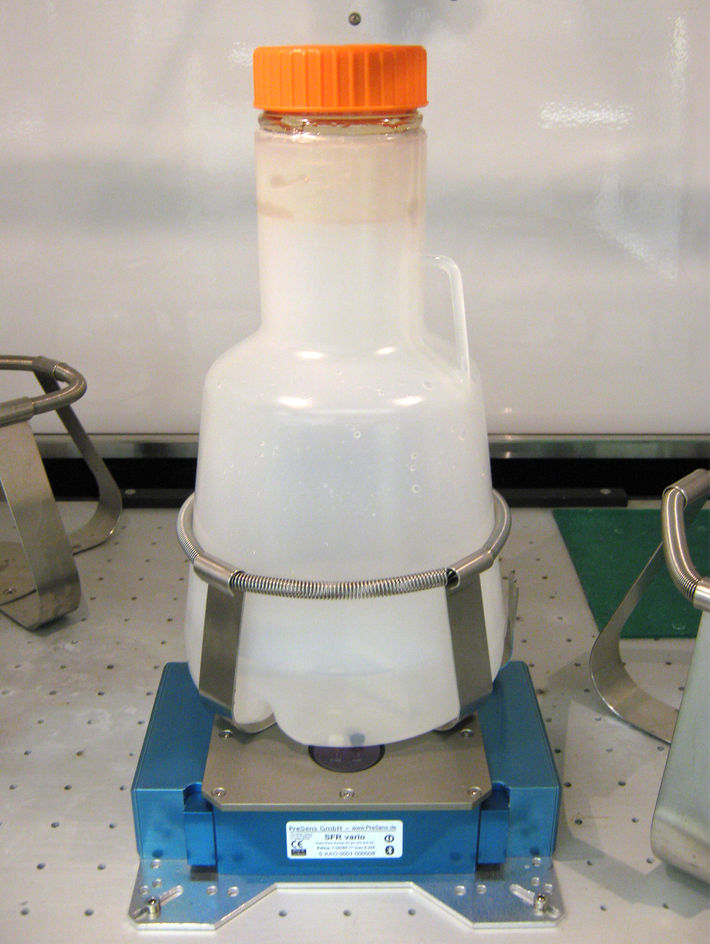

SFR vario Used with Only Slightly Translucent Shake Flasks

C. Ude and G. T. John

PreSens Precision Sensing GmbH, Regensburg, Germany

In this study we analyzed, if slightly translucent polypropylene shake flasks can be used for optical measurements and especially optical biomass monitoring with the SFR vario. As a prominent example we used Ultra Yield® flasks by Thomson for a C. glutamicum culture while monitoring O2, OUR, pH and biomass online.

Ultra Yield® flasks have a special 6 baffle design which promises to achieve higher aeration. This makes these disposable shake flasks interesting for E. coli and other microbial cultures. Compared to PreSens Sensor Flasks SFS (Corning) the Ultra Yield® flasks are only slightly translucent. Here we used a 2.5 L Ultra Yield® flask with the SFR vario sensor module for online measurements throughout a C. glutamicum batch cultivation. We integrated oxygen and pH sensors at the flask bottom that were read by the SFR vario. The PreSens Flask Studio software then calculated OUR automatically from the oxygen measurements. Therefore, kLa of Ultra Yield® flasks was determined which showed that it is in a similar range as that of PreSens Sensor Flasks SFS. Biomass was monitored optically – light is irradiated through the flask bottom, scattered by the cells in the culture broth and the backscattered light is then detected with the SFR vario.

Materials & Methods

C. glutamicum was grown in complex medium in a 2.5 L Ultra Yield® Flask with 20 % filling volume at 30 °C and 300 rpm (shaking diameter 25 mm). The flask was closed with a fitting Corning cap. One oxygen and one pH sensor spot (SP-PSt3, SP-HP5) were integrated at the flask bottom and oxygen, OUR, pH and biomass were monitored over a period of 25 h with the SFR vario inside the shaking incubator (see Fig. 1). Samples for offline OD600 measurements were taken from a parallel cultivation growing in the same conditions.

Results

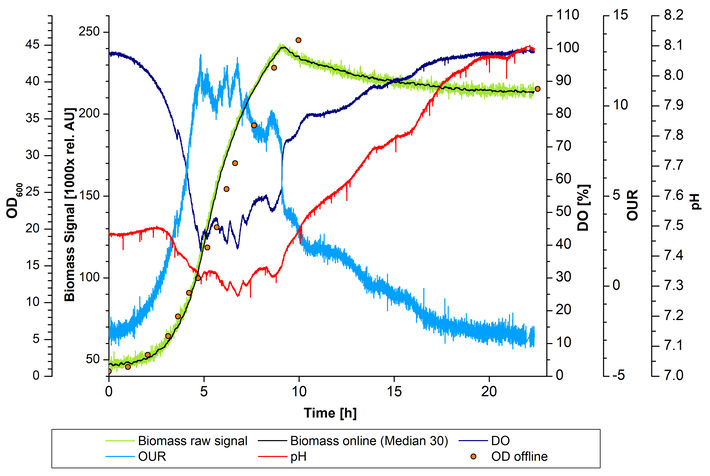

Figure 2 shows the online recorded data of the C. glutamicum culture and offline determined OD600 values. After about 1.5 h increased oxygen consumption sets in. For the next 10 hours the DO and OUR graphs show several peaks which indicate several metabolic shifts due to consumption of different carbon sources (e. g. Glucose, Acetate) in the complex medium. The pH drops by 0.24 during high metabolic activity while the culture continues to grow acidic, when metabolic products start to accumulate in the culture broth. In the second phase of cultivation after 7 hours a switch from carbohydrates to peptides and amino acids as carbon source leads to strong basification of the medium, which can be perfectly resolved by the HP5 sensor spot. After a short lag phase in the beginning the biomass curve clearly shows exponential growth from hour 4 onward, corresponding with the elevated oxygen uptake rate. After 9 h the exponential growth stops, and biomass decreases minimally until the cultivation is terminated. Oxygen consumption also continues for another 5 hours, indicating that further metabolic activity takes place, probably metabolizing some cells, before the death phase sets in. The offline OD600 data corresponds well with the online biomass data. The slight deviation between online and offline measured data might derive from the fact, that offline data was taken from a parallel cultivation. Under the conditions chosen oxygen never becomes limiting and the DO level does not drop below 40 %. The SFR vario data indicates, although there is still some metabolic activity, there is no more growth after 10 hours and the culture could be terminated then.

Conclusion

Our tests showed that conclusive online measurement data can be gathered with the SFR vario in translucent polypropylene shake flasks. In this example we were able to follow biomass development and metabolic activity in detail in Ultra Yield® flasks equipped with optical sensor spots. The online data of several parameters gathered simultaneously with SFR vario proved to give valuable insight into metabolic processes and enables for precise estimation of growth phases as well as nutrient availability by indirectly mining information from DO and pH data.