Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Measure Dissolved & Gaseous Oxygen Traces

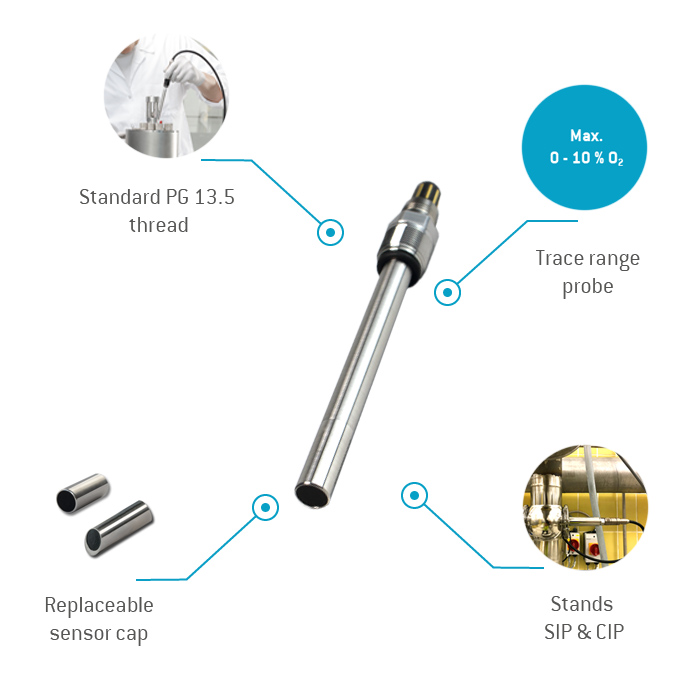

Trace Range Oxygen Probe OXYPro® TR & TRM

(max. 0 - 10 % O2)

The OXYPro® TR & TRM combine an optical sensor type PSt6 and electro-optical module in one probe. The sensor has a maximum measurement range of 0 - 10 % O2, and is integrated in a removable sensor cap (OEC), which can easily be exchanged. These trace range probes are perfectly suited for application in the brewing industries. The sensor caps are not only available in a version safe for food applications but also for different other demands like fast response time, or for measurements in aggressive environments. The OXYPro® are directly connected to the control unit and have a standard PG 13.5 stainless steel thread for easy integration at the measurement site. As a digital interface these probes use RS485 (OXYPro® TR = PreSens proprietary, OXYPro® TRM = Modbus RTU) and have 4 - 20 mA analog output. A serial communication protocol is offered for data exchange between the OXYPro® and a PC or other host unit. For initial operation and adjustment of the 4 - 20 mA output the PreSens EOM-STS software can be used.

- Maximum measurement range of 0 - 10 % O2, detection limit 0.002 % O2 / 1 ppb

- Ideal for O2 measurements in breweries

- Different versions: food applications, reduced bubble formation, aggressive environments

- Stands SIP (+ 140 °C, 1.5 atm) & CIP (+ 80 °C, 2 % NaOH)

- Simple integration due to standard PG 13.5 thread & Varivent adapter

- Communication via RS485 (PreSens proprietary, Modbus RTU)

- 4 - 20 mA output

Applications

Process Control in the Beverage Industries

Even low oxygen concentrations influence shelf-life and the taste of certain beverages. Due to the extraordinary low detection limits and outstanding accuracy of the OXYPro® MR and OXYPro® TR, the quality of oxygen-sensitive products such as beer, wine and soft drinks can be secured. With OXYPro® certain processes can be monitored and controlled. As the probes are autoclavable, stand SIP and CIP they are ideally suited for application in the beverage industries.

Monitoring Industrial Processes

The OXYPro® series probes are designed for harsh measurement conditions. Additionally they are almost maintenance-free as they do not contain any membranes and electrolytes, so they are ideally suited for monitoring chemical industrial processes or oxygen sensitive applications. They can be used for gaseous or dissolved oxygen monitoring in most different environments, like e. g. tubes or vessels.

Technical

| Specifications | Gaseous & Dissolved O2 | Dissolved O2 |

|---|---|---|

| *at 20 °C, 960 - 980 hPa; humidified gas mixture **after customized calibration ***determined changing from 10 % oxygen gas to nitrogen 5.0 ****determined changing from air-saturated water to a freshly prepared 1 % sodium sulfite solution *****not for OEC-PSt6-NAU-OIW; this sensor cap cannot be sterilized or autoclaved | ||

| Measurement range* | Optimal: 0 - 5 % O2, 0 - 50 hPa Max.**: 0 - 10 % O2, 0 - 100 hPa | Optimal: 0 - 2 mg/L Max.**: 0 - 4.5 mg/L |

| Limit of detection* | 0.001 % O2, 0.01 hPa | 0.5 ppb |

| Resolution* | 0.002 % O2 ± 0.0006 % O2 0.2 % O2 ± 0.001 % O2 | 1 ppb ± 0.3 ppb 20 ppb ± 0.4 ppb |

| Response time (t90) | < 10 sec.*** | < 30 sec.**** |

| Properties | ||

| Compatibility | Aqueous solutions | |

| No cross-sensitivity to | pH 1 - 14, CO2, SO2, ionic species | |

| Cross-sensitivity to | Organic solvents, such as pure acetone, toluene, chloroform or methylene chloride Chlorine gas | |

| Sterilization procedure***** | Steam sterilization (max. + 140 °C, 1.5 atm) | |

| Cleaning procedure***** | Cleaning in place (CIP, 2 % NaOH, + 80 °C, + 176 °F) 3 % H2O2, acidic agents (HCl, H2SO4) max. 4 - 5 % Ethanol, methanol, cleaning agents at room temperature | |

| Storage stability of sensor cap | 5 years provided the sensor material is stored at room temperature in dry conditions and in the dark | |

| Sampling rate | 1 sec. up to 9 min. 59 sec. | |

| Temperature sensor | NTC | |

| Accuracy of temperature measurement | ± 1 °C in operation temperature range (0 °C to + 50 °C) | |

| Power supply | 7 - 24 V DC | |

| Power consumption in active mode | Max. 1 W | |

| Power consumption in stand-by mode | 0.15 W | |

| Temperature range operation | Optimal: 0 °C to + 50 °C Max.: - 10 °C to + 90 °C | |

| Storage conditions | Optimal: room temperature (+ 20 °C ± 5 °C) Max.: 0 °C to + 70 °C, 80 % rel. humidity | |

| Pressure resistance at 20 °C | - 1 bar to + 12 bar | |

| Dimensions | Max. immersion depth: 120 mm / 225 mm / 325 mm / 425 mm + 7 mm with OEC30 PG 13.5 thread and VP8 connector: 55 mm Diameter: 12 mm | |

| Probe housing material | Stainless steel 1.4435 | |

| Surface quality of steel | Ra < 0.4 μm (N5) | |

| Wetted part | Stainless steel 1.4435, silicone, EPDM | |

| Weight | 100 g | |

| Digital interface | RS485, half-duplex (variable Baud rate, default: 19200, data bits: 8, parity: none, stop bits: 1, handshake: none) or RS485 Modbus RTU | |

| Analog output | 4 - 20 mA (current sink) | |