Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Measurements Under Real Conditions with Pre-Calibrated Sensors

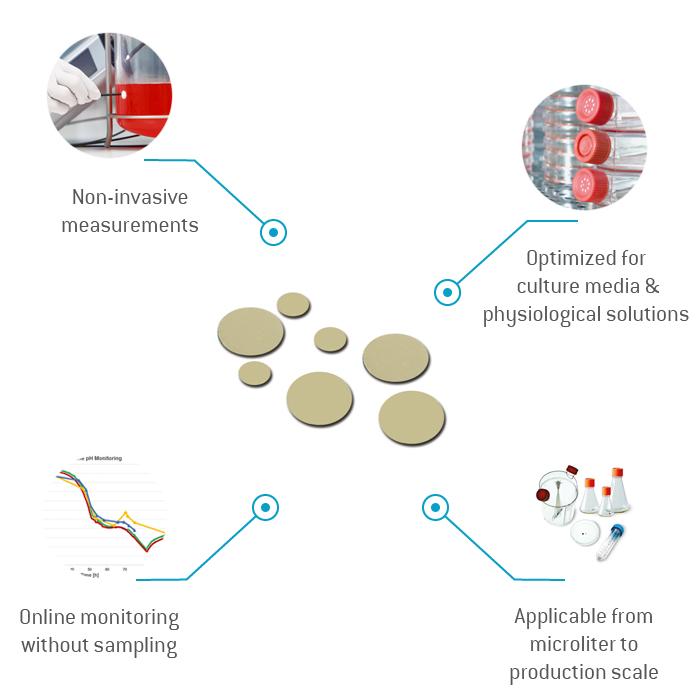

pH Sensor Spots SP-HP5

The SP-HP5 allow online monitoring and are optimized for physiological solutions and culture media. The spots are mounted in transparent vessels made of glass or plastic and then read out contactless from the outside - through the container wall. The sensors are pre-calibrated and ready-to-use.

- Online monitoring without sampling

- Contactless measurements through the vessel wall

- Pre-calibrated

- Applicable from microliter to production scale

- Optimized for culture media and physiological solutions

Applications

Bioprocess Development: pH Monitoring in Shake Flasks

The pH is one of the major issues in the cultivation of cells, yeast or bacteria. Shake flask cultures are widely applied in academic and industrial bioprocess development. As adequate methods for real monitoring of pH were not available, cumbersome at-line sampling was used. The combination with non-invasive oxygen sensors in shake flasks provides new insights into metabolic activity and changes in metabolic pathways.

Technical

| Specifications* | |

|---|---|

* provided pH sensors are used without further handling in physiological solutions | |

| Measurement range | 5.5 - 8.5 pH |

| Resolution | at pH = 7: ± 0.01 pH |

| Accuracy** | at pH = 7: ± 0.05 sensor spot calibration at pH = 7: ± 0.10 sensor batch calibration |

| Drift | at pH = 7: < 0.005 pH per day (sampling interval of 1 min.) |

| Measurement temperature range | from + 5 to + 50 °C |

| Response time (t90)** | < 120 sec. |

| Properties* | |

| Compatibility | Aqueous solutions, ethanol (max. 10 % v/v), methanol (max. 10 % v/v), pH 2 - 10 |

| Cross-sensitivty | Reduced to ionic strength (salinity); a high concentration of small fluorescent molecules in the visible range can interfere |

| Cleaning procedure | pH spots are delivered either beta-irradiated or untreated, a second irradiation or ethylene oxide treatment is not recommended |

| Sterilization procedure*** | Irradiation Ethylene oxide (EtO) Autoclaving (one time) |

| Calibration | pH spots are pre-calibrated; re-calibration is possible |