Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Homogeneous Oxygen Ingress and Evaporation in Shaken Cultures

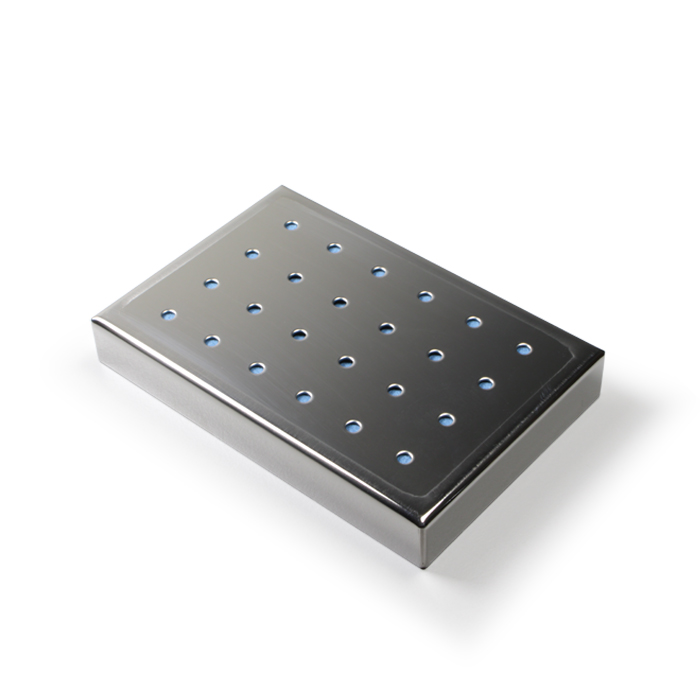

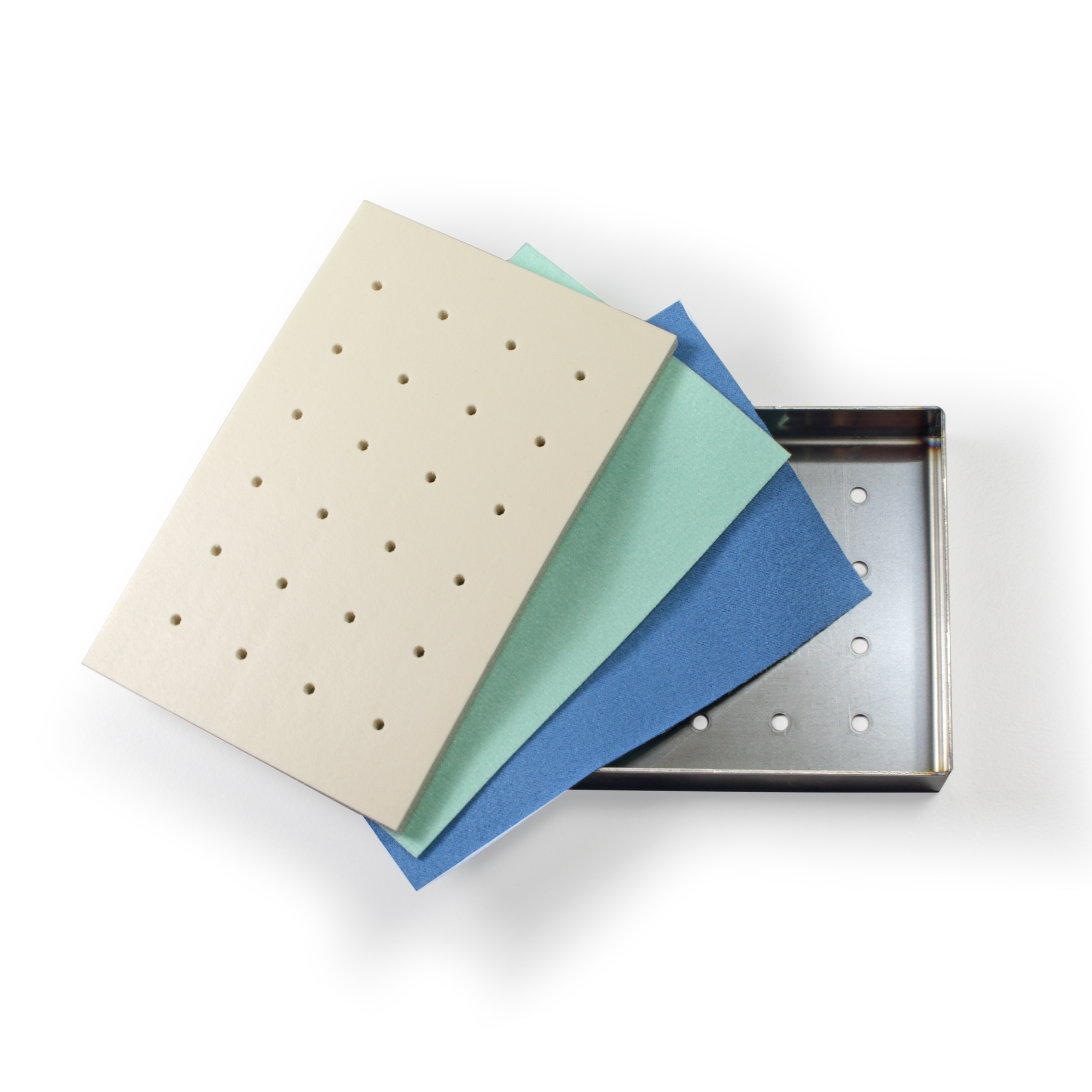

Sandwich Cover for 24-Well Deep Well Plates

This metal cover by Enzyscreen has 24 holes and contains 3 different layers made from different materials to ensure homogeneous oxygen ingress and evaporation in all 24 wells of Deep Well SensorDishes® during shaken cultivation. This enables comparing measurements from all wells, without edge effects and different conditions in outer or central wells. At the same time the cover avoids contaminations.

Please contact our service team for more information!

- Suitable for Deep Well SensorDishes®

- Homogeneous O2 ingress & evaporation in all 24 wells

- Autoclavable

Applications

Assessing Optimal Growth Conditions for Shaken Yeast Culture

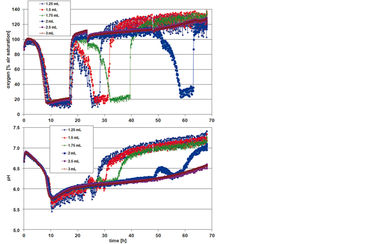

The yeast P. guillermondii was cultivated in deep well Oxo- and HydroDishes to examine growth profiles and determine the minimal filling volumes for sensor read-out at a shaking speed of 200 rpm. As no optical shielding mask (SDR-OSM24) was used in these experiments, recordings show a higher noise-ratio at lower filling volumes. Both oxygen and pH kinetics show clearly when the initial substrate is consumed and the cultures switch to metabolise another substrate. This substrate change correlates with the filling volume, as low volume samples had better oxygen supply and grew faster, so the initial substrate was used up earlier. The optimal working volume for yeast cultivation in the deep well plates is 1.25 - 1.5 mL.

Thomas Grimm, BIOWORX, Berlin, Germany

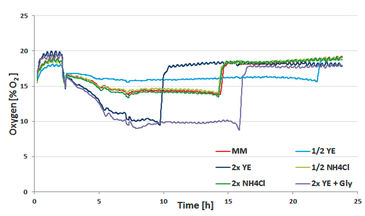

Evaluating the SDR & OxoDishes® for Strain Development

Oxygen kinetics during a shaken E. coli cultivation were monitored using a Deep Well OxoDish®. Different media compositions were tested and compared to a minimal medium (MM). A higher concentration of yeast extract (YE) led to faster growth. Addition of glycerine as a second substrate prolonged the stationary phase. Ammonium chloride had no influence on the metabolism. After the substrate(s) was consumed, oxygen increased due to oxygen ingress.

Olaf Christensen, Lonza Ltd., Visp, Switzerland

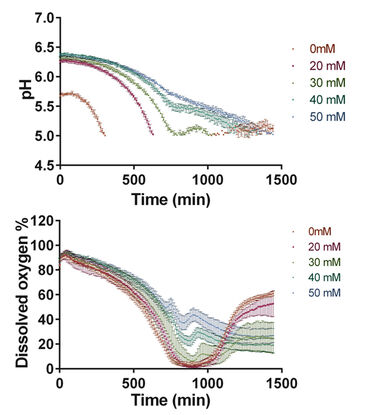

Improving Culture Conditions of Antibody-Producing Yeast

Reliable screening set-ups are the key to rapid identification of genetic modifications or changes of cultivation conditions improving strain performance. Using Deep Well SensorDishes® to improve culture conditions for antibody-producing S. cerevisiae strains, it was found that increasing the buffering capacity of standard synthetic yeast media affects the stability of the secreted antibody. Furthermore, it was detected that the media modification also affected dissolved oxygen levels during batch growth of the strain.

l. Kirjavainen and A. Frey, Aalto University, Finland

Technical

| Specifications | |

|---|---|

| Dimensions | 125 x 85 x 19 mm |

| Weight | 170 g |

| Materials | Metal cover, micro fiber filter inlay, expanded PTFE filter (0.3 micron), silicone seal |

| Compatibility | 24-Well (Deep Well) SensorDishes® |

| Sterilization procedure | Autoclaving (20 - 30 min at 121 °C, and 1 h at 100 °C for drying) |