Watch tutorials, webinars and informative videos about PreSens optical sensor systems.

Micro-invasive Measurements with Sensor Tips Thinner than a Hair

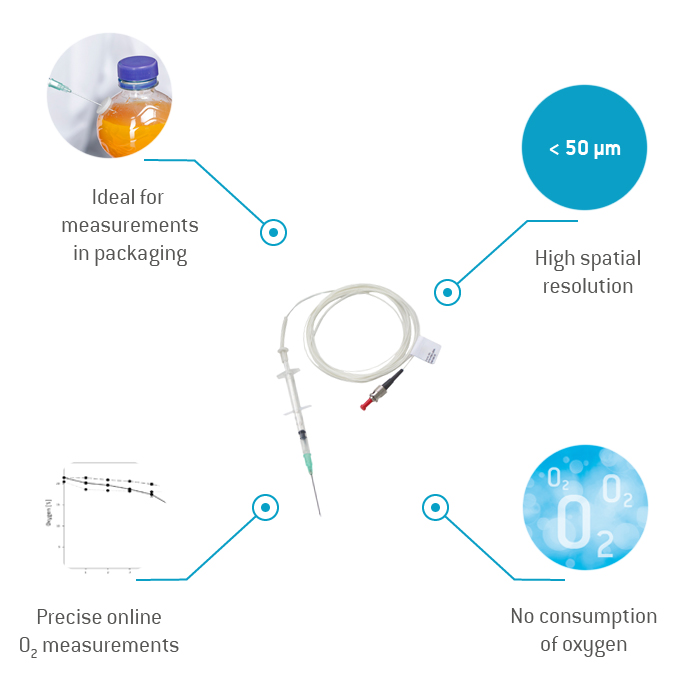

Needle-Type Oxygen Microsensor NTH-PSt1

This sensor is a miniaturized optical oxygen sensor designed for all research and packaging applications where a small tip size (< 50 µm tapered sensor tip TS, < 140 μm flat-broken sensor tip TF) and fast response time (t90 < 3 s) are necessary. It is mounted inside a stainless steel needle, which protects the optical fiber and oxygen-sensitive sensor tip. This design is optimal for easy penetration of tissue, septum rubber or packaging materials. After penetration the sensor tip is extended for measurements.

- High spatial resolution (down to < 50 μm)

- High temporal resolution (t90 < 3 sec.)

- No consumption of oxygen

- Signal independent of flow velocity

- Measures in liquids as well as in gas phase

Applications

Packaging & Quality Control

Oxygen inside packaging can lead to oxidative deterioration of certain products. Therefore, determination of the oxygen content within packages or pharmaceutical vials is of essential importance to ensure both the filling quality and the long-term storage stability. With our micro-invasive needle-type oxygen microsensors we offer a simple tool to determine residual oxygen both in the headspace and in liquids. The septum of the vial or package is pierced with the needle and the sensor is extended for measurement. As the measurement is made inside the package no error-prone and time consuming sampling is necessary. These oxygen microsensors are ideal tools for quality control in the food & beverage, packaging, and pharmaceutical industries.

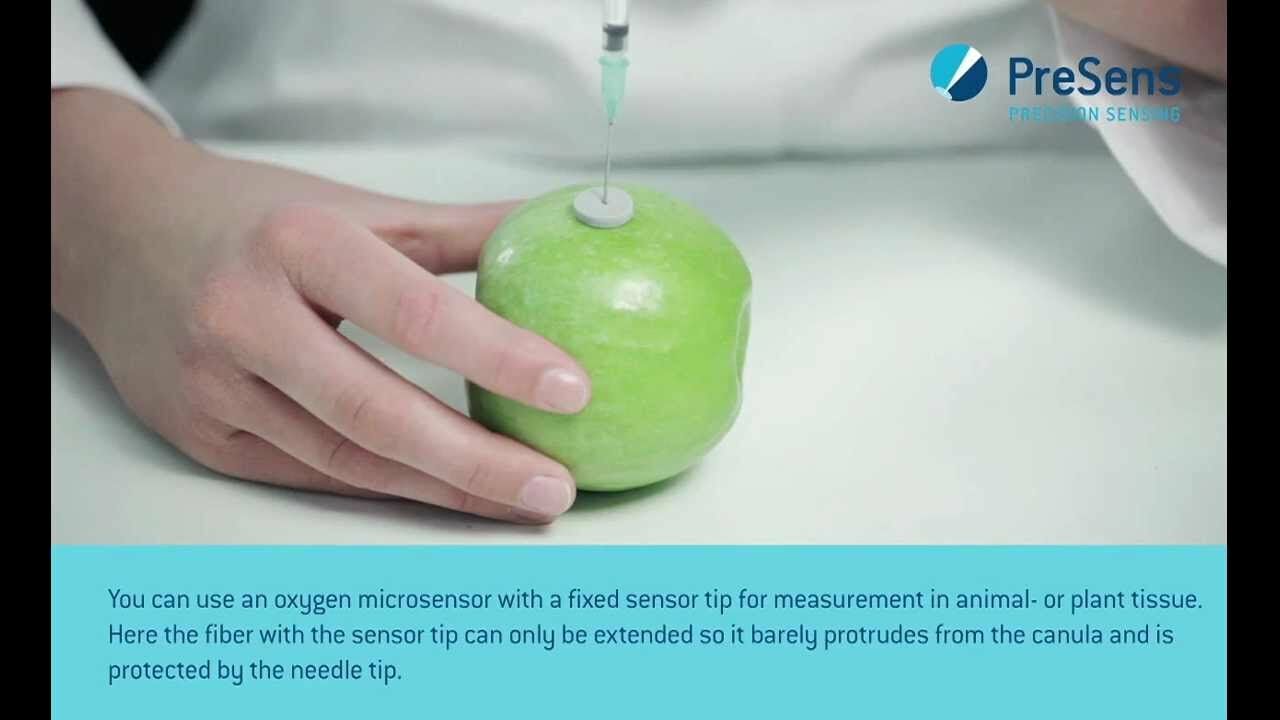

Tissue Engineering

Oxygen microsensors measure the oxygen content in various volume compartments of the tissue engineering constructs. To do so, hair-thin sensors are inserted into the constructs and the oxygen content is measured online. In this way, the oxygen partial pressure is measured with a high local resolution and correlated with the constructs tissue quality (composition of the extracellular matrix).

Technical

| Specifications | Gaseous & Dissolved O2 | Dissolved O2 |

|---|---|---|

| *after two-point calibration as described in the manual **TS: tapered sensor tip with a diameter < 50 μm and no optical isolation ***TF: flat-broken sensor tip with a diameter of 140 μm | ||

| Measurement range | 0 – 50 % O2 0 – 500 hPa | 0 – 22.5 mg/L 0 – 700 µmol/L |

| Limit of detection | 0.05 % oxygen | 20 ppb |

| Resolution | ± 0.01 % O2 at 0.21 % O2 | ± 0.005 mg/L at 0.09 mg/L |

| Accuracy* | ± 0.4 % O2 at 20.9 % O2 ± 0.05 % O2 at 0.2 % O2 | |

| Drift | < 0.1 % O2 within 30 days (sampling interval of 1 min.) | |

| Measurement temperature range | from 0 to + 50 °C | |

| Response time TS** (t90) | < 1 sec. (gas) | < 2 sec. (liquid) |

| Response time TF*** (t90) | < 15 sec. (gas) | < 30 sec. (liquid) |

| Properties | ||

| Compatibility | Aqueous solutions, ethanol, methanol | |

| No cross-sensitivity | pH 1 – 14 | |

| Cross-sensitivity | Organic solvents, such as acetone, toluene, chloroform or methylene chloride Chlorine gas | |

| Sterilization procedure | Ethylene oxide (EtO) | |

| Cleaning procedure | 3 % H2O2 Ethanol Soap solution | |

| Calibration | Two-point calibration with oxygen-free environment (nitrogen, sodium sulfite) and air-saturated environment | |

| Storage stability | 60 months provided the sensor material is stored in the dark at room temperature | |

Related products

Resources

FAQs

Manuals

Brochures

Software

PreSens Oxygen Calculator version 3.1.1 - Windows 7/8/10